Crankshaft is a mechanical and important part of the engine which facilitates to perform a conversion between reciprocating motion and rotational motion. The tolerances of the crankpin and main journal of the crankshaft are generally very close in order to have longer life and continuous satisfactory performance of Crankshaft without any damage. It is important that crankshaft tolerances are always maintained strictly as per original tolerances.

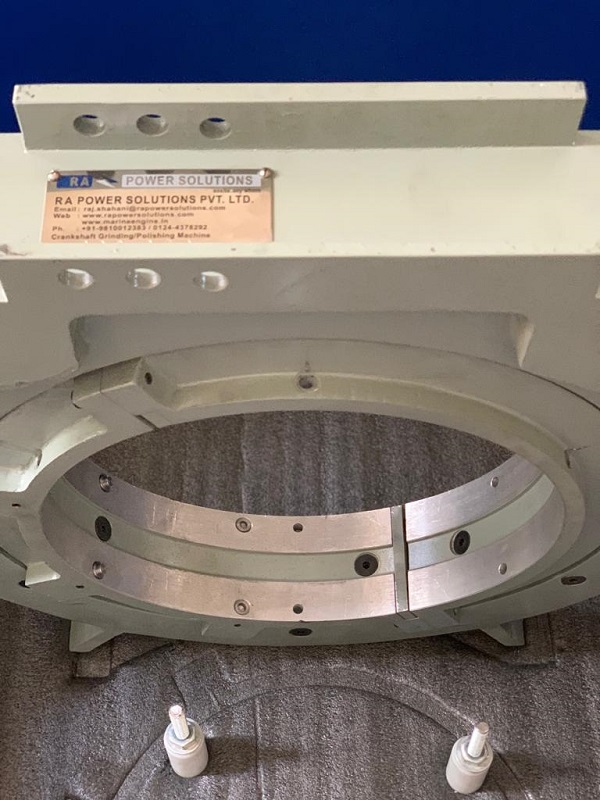

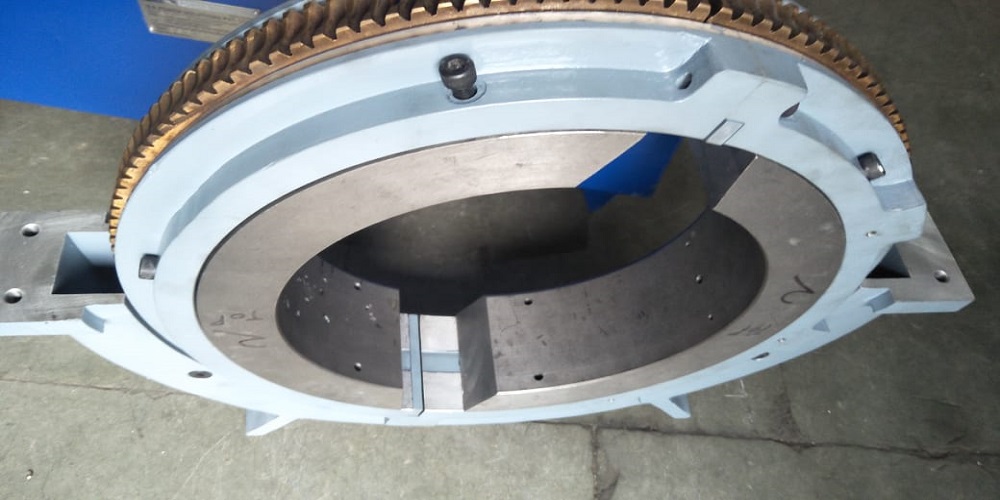

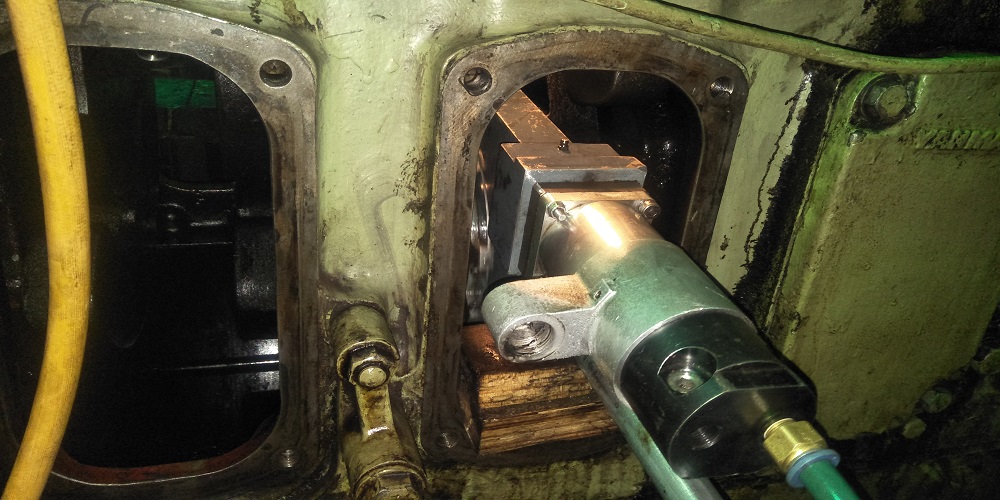

RA Power Solutions design and manufactures insitu crankshaft grinding and polishing machine. The insitu crankshaft machine is of advanced technology which is designed to maintain the crank pin and main journal tolerances in terms of taper, ovality, and surface finish strictly as per the manufacturer’s specifications. There is no need of disassembly /removal of the crankshaft from the entablature. The onsite crankshaft grinding and polishing machine manufactured by RA Power Solutions is available in the range of 35 mm to 700 mm in terms of diameter.

The onsite crankshaft grinding machine is light in weight and can be easily taken to the far of places all over the world. The onsite crankshaft grinding and polishing machine has the following features:

- Technologically advanced crankshaft machining equipment in comparison to the conventional and old cage type design which is outdated.

- Onsite crankshaft grinding and polishing machine does not require any reference of radius fillet for machining of crankpin/main journal of the crankshaft.

- Onsite crankshaft grinding and polishing machine frame is made out of titanium steel which is robust and vibrationless.

- With our latest onsite crankshaft grinder, machining of crankshaft up to 700 mm diameter can even be done while sailing of the vessel maintaining the close tolerance.

- Onsite crankshaft grinding machine capable of maintaining close tolerance within 0.02 mm and with high surface finish fa better then the international standards.

- The insitu crankshaft grinding machine manufactured by RA Power solutions can also be used for a cylindrical shaft grinding and polishing and for repair of alternator, rotor shaft, pump shaft, intermediate shaft, mid shaft and turbine shaft.

- Insitu crankshaft grinding and polishing equipment is easy to operate and maintain. It does not require any complicated day-to-day maintenance.

- We are giving free training to the client’s technicians for operation of this latest onsite crankshaft grinding equipment.

The cost of insitu crankshaft machining equipment is low and affordable. Highly recommended for large diesel power plants, shipping companies, and engine repair workshops. Insitu crankshaft grinding equipment is supplied in sturdy steel boxes that can be easily stored and taken from one site to another.

We have sold more than 70 crankshaft grinding machines all over the world including South America, UK, Italy, Nigeria, Singapore, Philippines, Iran, Dubai, and various countries.

The author of this blog is Mr. Raj Shahani (Managing Director of Company). He has four decades of experience in the field of high-capacity engine repair and grinding of shaft. He has developed an onsite crankshaft grinding machine to make the grinding process easy and less time-consuming. With the development of grinding equipment, now companies can undertake grinding and repair of any rotary shaft themselves saving a huge amount of money and time.

For information regarding onsite crankshaft grinding & polishing machine, on site machining services, onsite crankshaft machining, contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

Crankshaft is a mechanical and important part of the engine which facilitates to perform a conversion between reciprocating motion and rotational motion. The tolerances of the crankpin and main journal of the crankshaft are generally very close in order to have longer life and continuous satisfactory performance of Crankshaft without any damage. It is important … Continue reading “In-Situ Crankshaft Grinding Machine | Onsite Crankshaft Machining | Onsite Crankshaft Grinding & Polishing Machine – RA Power Solutions”