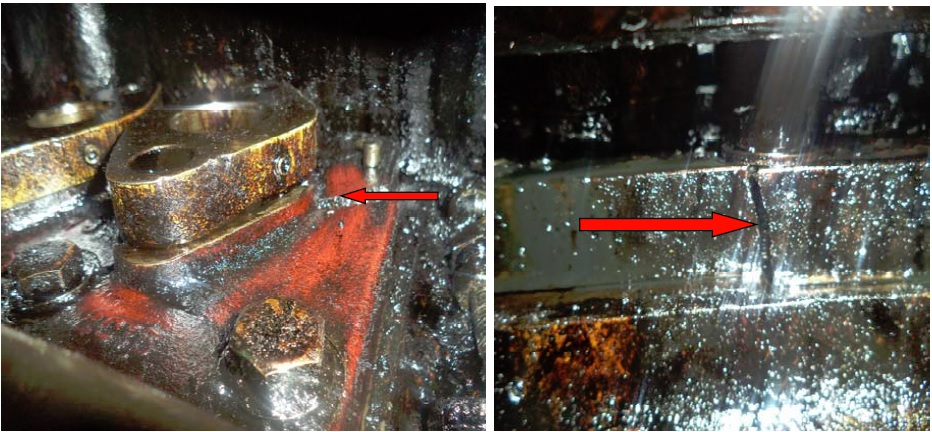

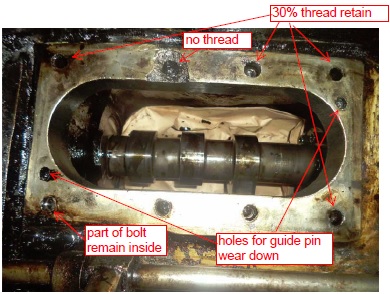

RA Power Solutions was informed by one of our client regarding damage of cam case cover of MAN diesel engine on board a vessel sailing near China. The details including photographs were examined, and it was observed while the cam case cover was broken into pieces the threads on the engine body and the dowel pin were also damaged.

RA Power Solutions deputed their team of technicians on board the vessel, and they executed the repair of engine block, cam case cover sitting area by the following procedure:

- The broken bolt which remained inside the thread hole was drilled out.

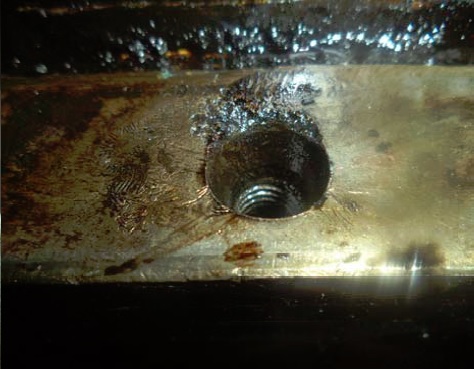

- The damaged threads on cam cover sitting area on entablature was removed by drilling new blind holes, suiting the new M12 Helicoil thread inserts.

- Re-tap holes for the new M12 Helicoil thread inserts was done carefully.

- New M12 Helicoil thread inserts were installed in the engine frame/ entablature.

- The 2 guide pins for the roller guide housing were removed, taking due precaution.

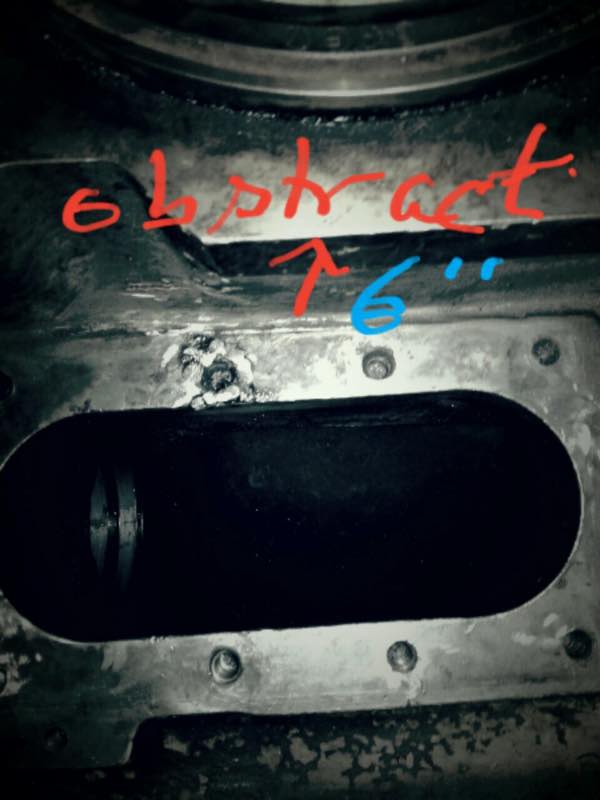

- New roller guide housing was installed, with correct M12 hexagon bolts and including the newly introduced 10 mm washers.

- After final alignment of the roller guide housing, the bolts were tightened with the correct tightening torque.

- Finally, the two ø8 mm guide pinholes were drilled in both roller guide housing and engine frame and afterwards new guide pins were installed.

The repair of threads by thread repair inserts (helicoil inserts) proved to be successful as the engine is performing satisfactory and no oil leakage is observed. The shipping company owners were asked to replace the complete engine block by the manufacturers as per them it was not possible to execute this kind of repair.

The above job was successfully executed by a team of experienced and dedicated team of RA Power Solutions.

The author is Mr. Raj Shahani Managing Director of RA Power Solutions having experience of almost four decades of working on high-capacity diesel engines, turbines and rotary equipments. The company specializes in executing the repairs i.e. metal stitching and metal locking, cold metal stitching engine block, grinding and repair of crankshafts, rebabbitting of bearings, connecting rod reconditioning, and overhauling of Engines which have serious problem resulting to the immense saving to the owners.

For more on metal stitching and metal locking, metal stitching of engine block contact us today email us at rajshahani@rapowersolutions.com, info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

RA Power Solutions was informed by one of our client regarding damage of cam case cover of MAN diesel engine on board a vessel sailing near China. The details including photographs were examined, and it was observed while the cam case cover was broken into pieces the threads on the engine body and the dowel … Continue reading “Metal Stitching and Thread Repair Inserts – RA Power Solutions”