RA Power Solutions, with 4 decades of experience, has now introduced an onsite crankshaft grinding machine which is portable and can undertake crankshaft machining, crankshaft grinding, and crankshaft repair onsite.

Now there is no need to remove the crankshaft from the engine block and send it to the workshop.

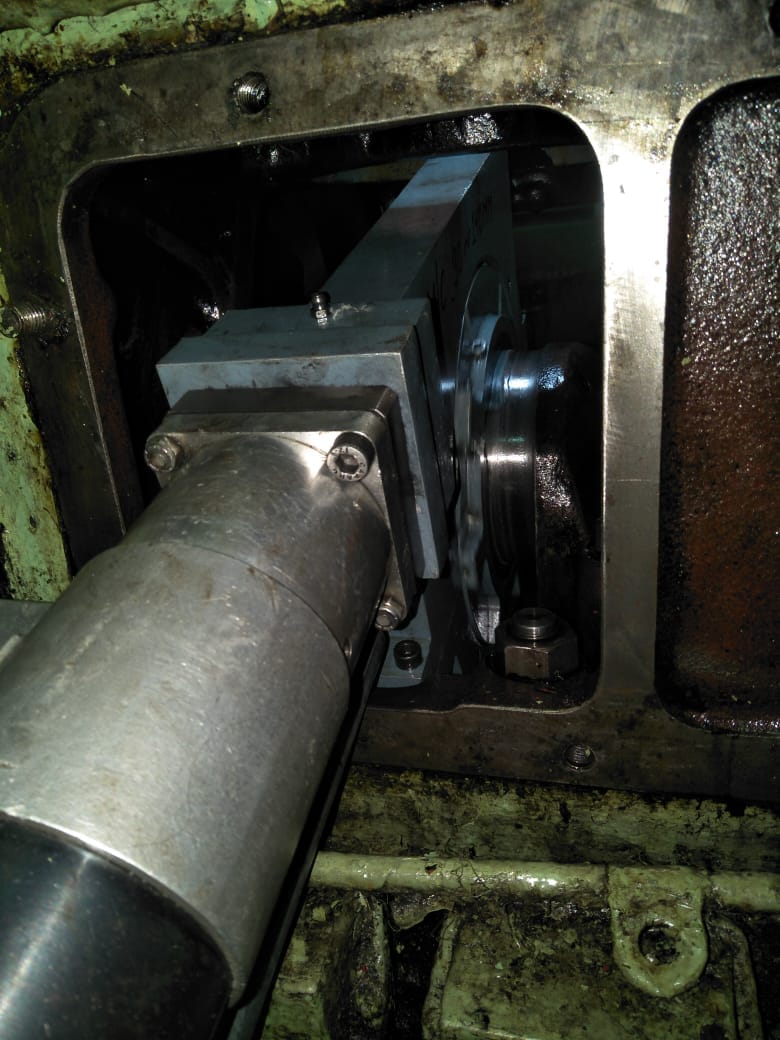

The crankshaft grinding machine has the following features:

I) The crankshaft grinding machine is introduced by RA Power Solutions, having experience of 4 decades in crankshaft repair.

II) After extensive trials and experience, we have introduced the machine in the open market. It is now available for shipping companies, engine repair workshops, power plants, and more.

III) The onsite crankshaft grinding and polishing machine is of the latest design, having minimum vibrations during operation. An onsite crankshaft grinding machine can be used while sailing the vessel.

IV) Tolerances achieved after crankshaft grinding and crankshaft polishing are far better than the manufacturer’s specifications. This is proven as repairs executed are class approved.

In case of emergency, we operate the onsite crankshaft grinding and polishing round the clock. The crankshaft grinding and polishing machine is easy to operate and job training is provided. This machine is supplied ready to use and complete in all respect. More than 100 machines supplied all over the world.

For more information on crankshaft repair and crankshaft grinding services, contact us by email at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs:

It is a portable, in-situ machine designed to grind and repair crankpins and main journals without removing the crankshaft from the engine block.

We can repair crankshafts with diameters up to 700 mm directly at the vessel, power plant, or industrial site.

Yes, our machine is lightweight, low-vibration, and capable of operating during sailing, reducing downtime.

It eliminates the need to dismantle the engine, saves time and money, and ensures repairs meet OEM tolerances.

Yes, we provide free onsite training for operators along with 24/7 support and worldwide service.