When accidents strike—despite the strictest maintenance—threads on engine blocks, turbine casings, and cam blocks often suffer damage, frequently accompanied by cracks around the threaded areas. RA Power Solutions has developed a robust, onsite repair process that restores functionality without dismantling the components.

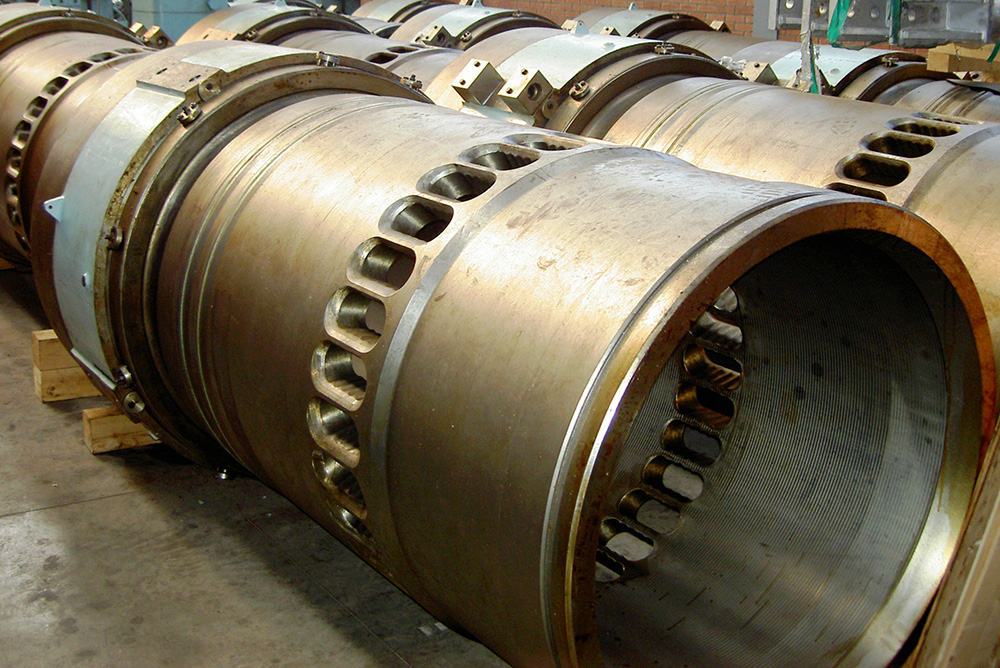

Wartsila 12V32 Engine Block Repair via Onsite Machining

RA Power repairs threads and cracks damaged in accidents. The advantages are:

- Conducted Magnetic Particle Inspection (MPI) across the engine block using Level 3 certified technicians to detect cracks.

- Performed dimensional measurement of main journal housings to assess taper and ovality.

- We carry portable, lightweight machines to the site to repair damaged threads.

- The team cut out the damaged block portion completely.

- Fabricated a new casting section matching the original Wartsila 12V32 block profile.

- Installed the new section using metal stitching and metal locking techniques.

- Finalized with onsite machining to restore main journal housing bore dimensions within manufacturer specifications.

Engine Block Repair | Onsite Machining | Crack Repair

Serving the diesel power plants and shipping companies for the last four decades, we observed that in spite of the best maintenance protocols and process followed, accidents do take place. We have the history of repairing seriously damaged engine blocks.

Recently, a Wartsila engine suffered heavy damage on both sides of the block measuring 600 mm × 500 mm. The accident also damaged the main journal housings. A barge with six Wartsila 12V32 units housed the engine.

Why RA Power Solutions Is Your Go-To for Engine Casting Repairs?

- Four decades of industry experience, serving diesel power plants and marine clients.

- Highly skilled teams capable of delivering on-the-spot repairs, minimizing plant disruptions.

- Our methods sidestep destructive heat-based procedures, offering cold, stress-free solutions.

- We’ve helped salvage thousands of components through repair methods that avoid needless replacements

For more information on Crack Repair for Engine Block, Thread Repair, contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs:

Yes, it can be repaired using metal stitching and onsite machining.

No, welding often causes heat stress—metal stitching is safer.

It’s far more affordable than replacing the entire engine block.

Yes, portable tools allow onsite repair without removal.

When accidents strike—despite the strictest maintenance—threads on engine blocks, turbine casings, and cam blocks often suffer damage, frequently accompanied by cracks around the threaded areas. RA Power Solutions has developed a robust, onsite repair process that restores functionality without dismantling the components. Wartsila 12V32 Engine Block Repair via Onsite Machining RA Power repairs threads and … Continue reading “Thread Repair Insert | Crack Repair Engine Block Cover | Onsite Machining – RA Power Solutions”