For over four decades, RA Power Solutions has led the industry in portable crankshaft grinding, enabling repair directly on vessels or in power plants—eliminating the need to dismantle or transport heavy engine components.

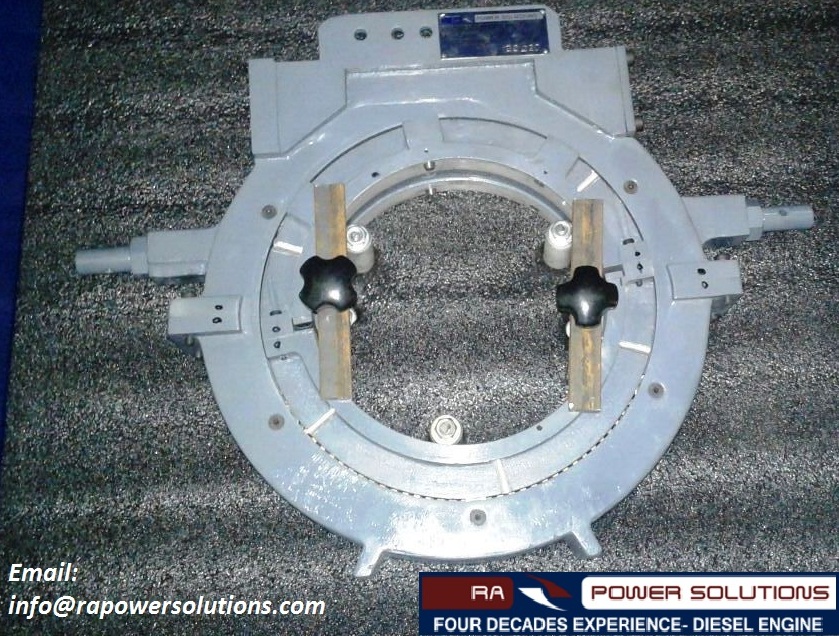

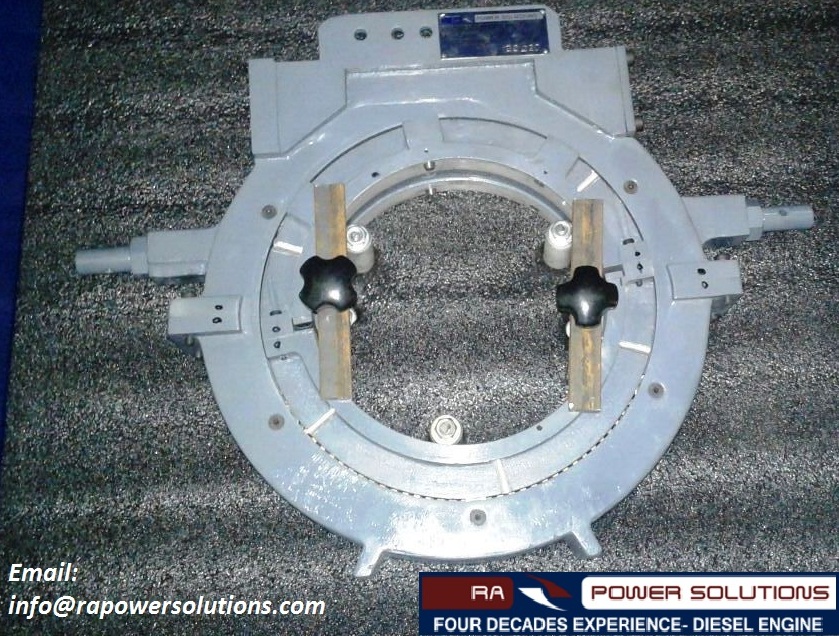

RA Power Solutions manufactures the insitu crankshaft grinding machine, which is lightweight, portable, and easy to operate. We developed and manufactured this revolutionary equipment.

Globally Deployed Machines & Capabilities:

- Designed for crankpin and main journal diameters between 35 mm and 700 mm—covering most diesel engine builds

- We have sold over 100 machines worldwide to shipping firms, power plants, and engine workshops. Clients are located in countries like Singapore, Nigeria, Italy, Saudi Arabia, and beyond.

- Combines grinding and polishing in one setup, with minimal vibration, maintaining tolerances as tight as 0.02 mm.

Key Features & Benefits:

| Feature | Benefit |

| Compact, lightweight design | Easily fits through engine inspection windows and transports globally with ease |

| Titanium‑steel vibration‑absorbing frame | Enables grinding even while the vessel is underway, preserving OEM tolerances |

| Electrical or pneumatic drives | Versatile operation adapted to client’s power infrastructure |

| On-job training included | Technicians learn how to operate and maintain the equipment directly from RA Power staff |

| Fully portable toolbox unit | Supplied ready-to-use in a steel box—ideal for rapid site deployment |

Why Onsite Grinding Beats Workshop Repairs?

- Reduces downtime by eliminating dismantling and logistics

- Cuts costs significantly versus sending crankshafts to external workshops

- Meets or exceeds OEM specifications, including taper, ovality, and surface finish.

Fully class-approved repair methods and international case studies support machine reliability worldwide.

Proven Track Record

- RA Power Solutions’ patented handheld machines have repaired over 10,000 crankshafts worldwide, delivering results trusted by shipowners and industrial clients alike.

- Ideal for marine engines, power-plant diesels, turbines, alternators, and general rotary equipment requiring precision journal repairs.

Get in Touch

Need emergency crankshaft repair or onsite polishing? RA Power Solutions offers Insitu Crankshaft Grinding Machine for 24/7 global service with immediate dispatch. Contact us:

Email: rajshahani@rapowersolutions.com or info@rapowersolutions.com

Phone: +91 9582647131 | +91 9810012383

FAQs:

Technicians use this portable machine to grind crankshaft journals directly on-site. It eliminates the need to dismantle the engine.

Our machines cover crankpins and main journals ranging from 35 mm to 700 mm in diameter.

The compact, vibration-free design allows technicians to use it on ships—even during voyages.

Machines can be operated with either pneumatic or electric power, depending on site conditions.

Yes, onsite training and support are included to ensure proper operation and maintenance.