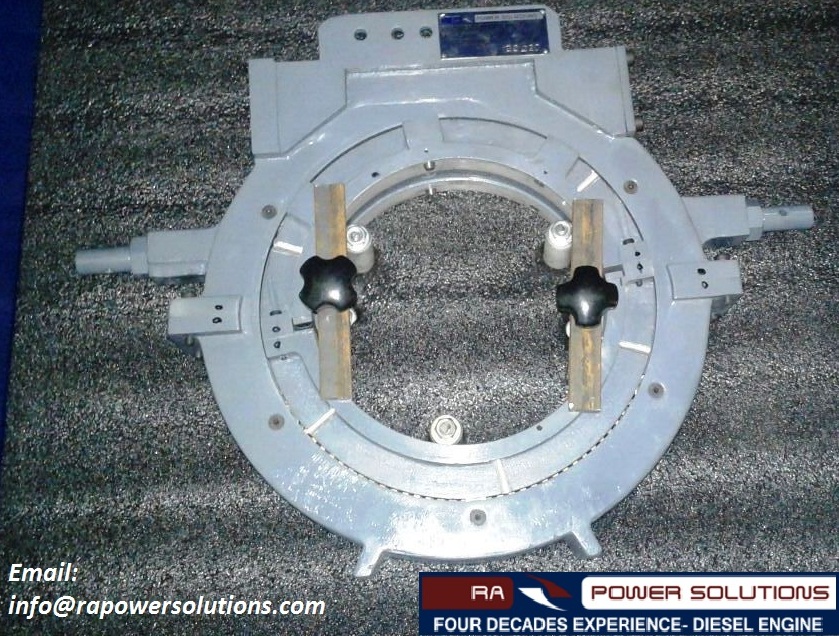

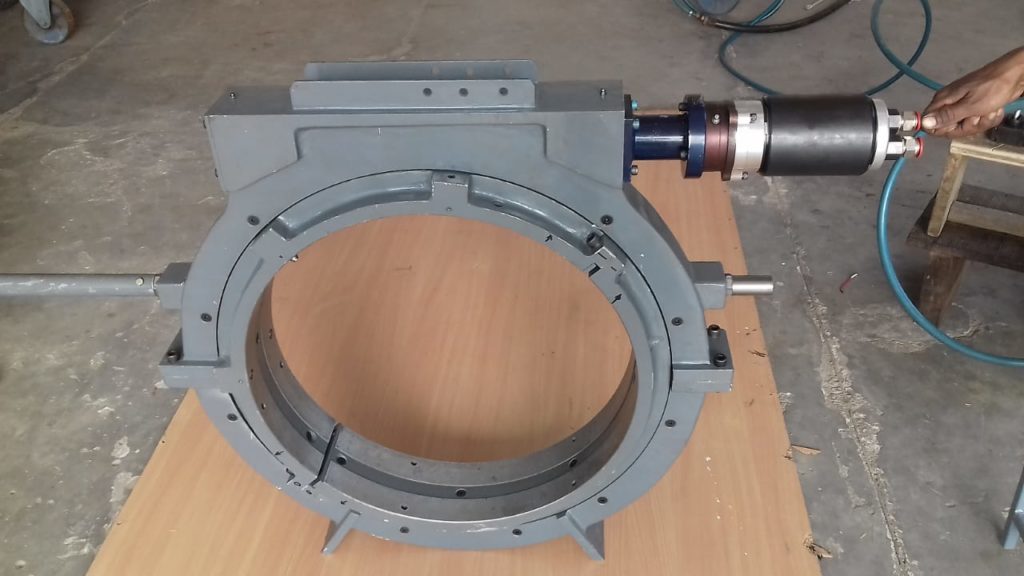

RA Power Solutions manufactures in situ crankshaft grinding and polishing machine. It is a revolutionary, lightweight, easy-to-operate, and compact crankshaft grinding and crankshaft polishing machine which can undertake the repair of crankpins up to the diameter of 700 mm without removing the crankshaft from the engine block.

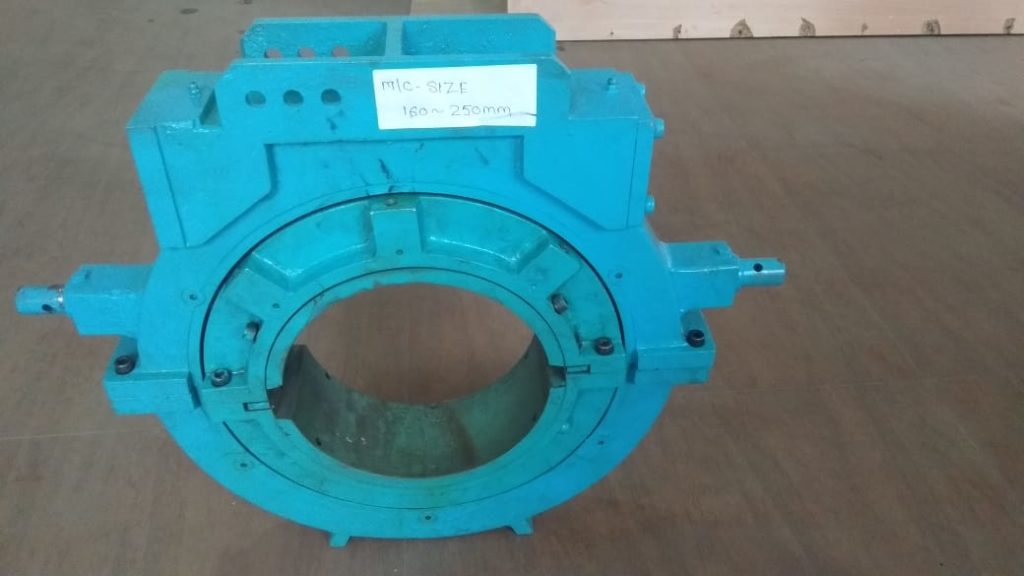

The in situ crankshaft grinding and crankshaft repair machine is a unique invention and is of great assistance to the shipping companies as they can not remove the crankshaft from the vessel and send it to the workshop for repair. Again, the crankshaft grinding machines installed in the workshop are not an ideal solution due to its high cost and lack of know-how to operate. RA Power Solutions manufactures and exports onsite crankshaft grinding and repair machines having a range of 35 mm to 700 mm in terms of the diameter of crankpin and main journal of the crankshaft.

Crankshaft Grinding Machine has the following features:

- Onsite crankshaft grinding and polishing machine is compact, lightweight, and can be inserted from the inspection window of the engine block.

- It is simple in design, easy to operate, and maintain

- Crankshaft grinding and polishing machine body is manufactured out of titanium steel having the property of absorbing the vibrations. With the vibration or almost zero vibration machine can also be used for crankshaft grinding and crankshaft repair while sailing of the vessel.

- All parameters and tolerances as recommended by the engine manufacturer can be strictly maintained.

- With the use of onsite crankshaft grinding and polishing machine, repair can be done in one setting. Thus saving the time.

- This crankshaft grinding and polishing machine is manufactured with a pneumatic or electrical drive depending on the client’s requirement.

- On Job training for the operation and maintenance of the crankshaft grinding machine is extended through our experienced technicians.

- Crankshaft repair machine is supplied in a toolbox and can be transported all over the world.

We have sold more than 70 crankshaft grinding machines all over the world that includes shipping companies, leading repair workshops and power plants, etc.

The author of the blog is Mr. Raj Shahani, Managing Director of the company. He is having 40 years of experience in solving the major issues related to repair and overhauling of engines, grinding and repair of the crankshaft, and many more related to the high capacity engine.

For more information regarding onsite machining of crankshaft, in situ crankshaft grinding repair, crankshaft grinding machines, onsite crankshaft grinding, and crankshaft polishing equipment, please email us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

RA Power Solutions manufactures in situ crankshaft grinding and polishing machine. It is a revolutionary, lightweight, easy-to-operate, and compact crankshaft grinding and crankshaft polishing machine which can undertake the repair of crankpins up to the diameter of 700 mm without removing the crankshaft from the engine block. The in situ crankshaft grinding and crankshaft repair … Continue reading “In Situ Crankshaft Grinding Machine | Onsite Crankshaft Grinding & Polishing Machine | Crankshaft Grinder – RA Power Solutions”