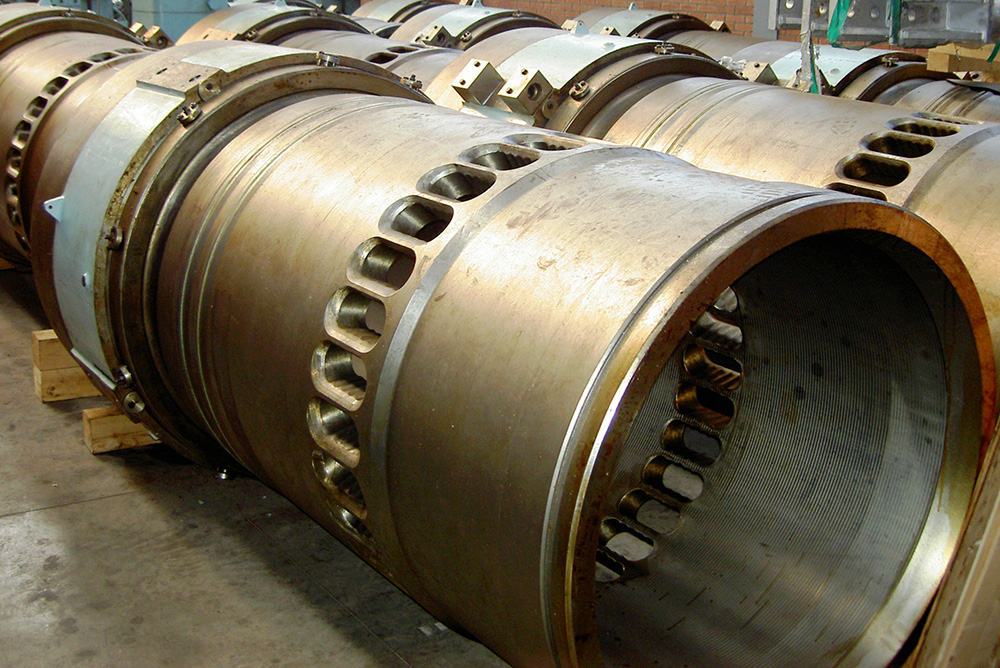

The cylinder liner has a significant impact on marine engine performance. RA Power Solutions manufactures and exports high-quality cast iron and alloy steel cylinder liners. We engineer them to OEM specifications and design them to withstand harsh marine environments.

Using Centrifugal Casting for Quality Manufacturing

Our cylinder liners are produced using a centrifugal casting process, which ensures defect-free walls and eliminates blow holes—critical for maintaining structural integrity and longevity.

In order to ensure the high quality of liner casting, we use a centrifugal process which ensures that there are no blow holes and any abnormalities in the casting of cylinder liners.

Engineered to OEM standards and ready to ship

With over 45 years of manufacturing excellence, we deliver liners up to 1,500 mm in length to a global network. Our products support leading marine engine brands—including MAN B&W, Cummins, Caterpillar, Wartsila, Mitsubishi, Volvo Penta, Yanmar, and more.

Why Choose RA Power Solutions for Cylinder Liners?

| Feature | Your Advantage |

| Centrifugal casting | Ensures uniform strength, avoids casting defects |

| Cast iron & alloy steel | Tailored to engine-specific requirements |

| Global export capability | Quick supply to shipyards and engine facilities worldwide |

| Experience & reliability | Over four decades of trusted performance in marine engine components |

For more information about Cylinder Liners, Marine Engine Cylinder Liners, contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs:

We manufacture cylinder liners using cast iron and alloy steel, tailoring the composition according to the specifications provided by engine manufacturers.

We employ a centrifugal casting process which ensures uniform grain structure, eliminates blow holes, and produces liners free from casting abnormalities.

We manufacture cylinder liners up to a length of 1,500 mm.

With over 45 years of experience and a global reach, we supply liners for top marine and industrial engine brands such as MAN B&W, Cummins, Caterpillar, Wartsila, Mitsubishi, Volvo Penta, Yanmar, and more.

Absolutely, Each liner undergoes stringent quality control, including dimensional inspection and metallurgical tests to verify composition and tolerances.

The cylinder liner has a significant impact on marine engine performance. RA Power Solutions manufactures and exports high-quality cast iron and alloy steel cylinder liners. We engineer them to OEM specifications and design them to withstand harsh marine environments. Using Centrifugal Casting for Quality Manufacturing Our cylinder liners are produced using a centrifugal casting process, … Continue reading “High Quality Cylinder Liners | Marine Engine Cylinder Liners”