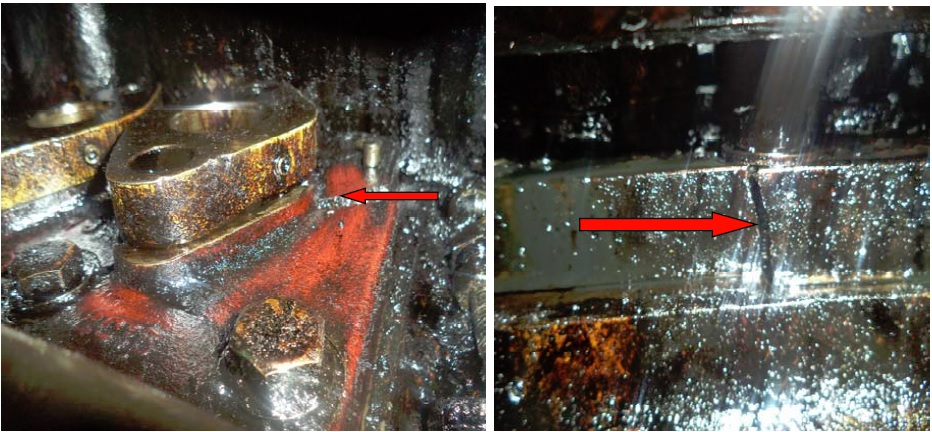

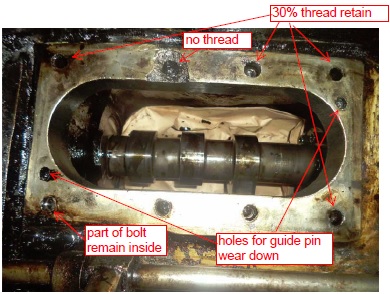

One of our clients informed RA Power Solutions about damage to the cam case cover of a MAN diesel engine on board a vessel sailing near China. After reviewing the details and photographs, we observed that the cam case cover had broken into pieces. We also found that the threads on the engine body and the dowel pin were damaged.

RA Power Solutions Executes Onboard Repair of Engine Block and Cam Case Cover Sitting Area:

RA Power Solutions deputed their team of technicians on board the vessel, and they executed the repair of engine block, cam case cover sitting area by the following procedure:

- The broken bolt which remained inside the thread hole was drilled out.

- The damaged threads on cam cover sitting area on entablature was removed by drilling new blind holes, suiting the new M12 Helicoil thread inserts.

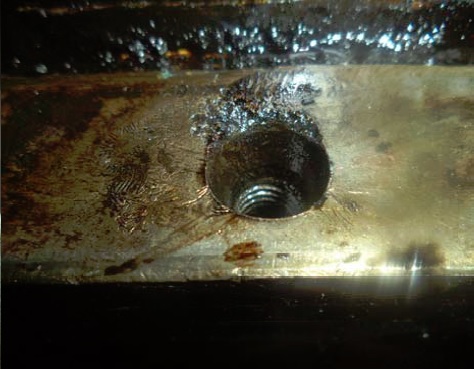

- Re-tap holes for the new M12 Helicoil thread inserts was done carefully.

- New M12 Helicoil thread inserts were installed in the engine frame/ entablature.

- The 2 guide pins for the roller guide housing were removed, taking due precaution.

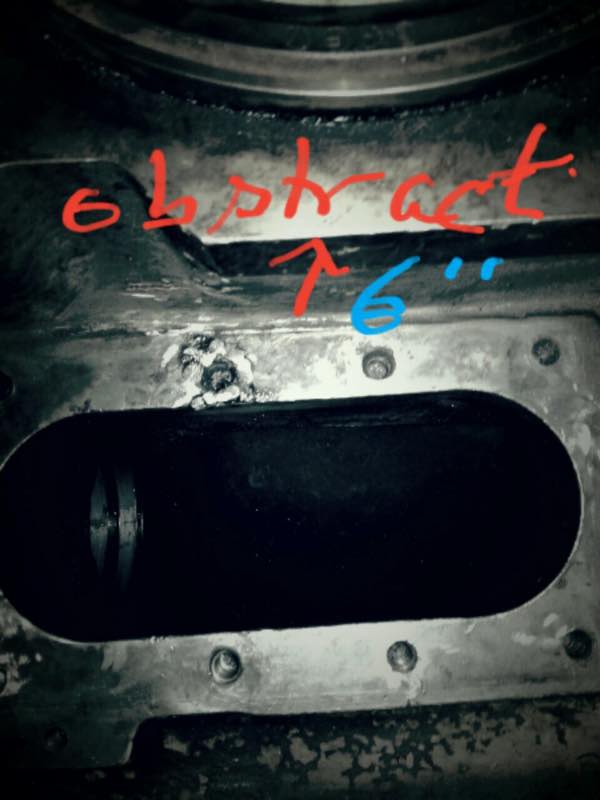

- Technicians installed a new roller guide housing using correct M12 hexagon bolts. They also included the newly introduced 10 mm washers.

- Technicians completed the final alignment of the roller guide housing. They then tightened the bolts using the correct tightening torque.

- Technicians drilled two ø8 mm guide pinholes in both the roller guide housing and the engine frame. Afterwards, they installed new guide pins.

What Is Metal Stitching?

Metal stitching, also known as metal locking, uses a cold repair technique to fix cracked or broken cast components. This method eliminates the need for welding. The process restores original strength and ensures pressure-tight sealing through mechanical locking of stitching pins and studs.

Advantages of Metal Stitching Over Welding:

- No heat means no distortion, warping, or residual stress

- Maintains alignment and surface profile of the original cast

- Suitable for cast iron, steel, aluminum, and other alloys

- Creates permanent, pressure- and liquid-tight repairs

- Enables on-site repairs with minimal disassembly

- Often stronger than the original material

Our Process at RA Power Solutions:

- Damage Inspection & Assessment: Document cracks and thread damage

- Thread Repair via Stitching & Inserts: Use stitching keys and Helicoil/insert methods

- Post-Repair Finishing: Grind and align to restore original surface

- Testing & Validation: Conduct pressure or stress tests to ensure integrity.

With decades of experience and advanced cold-repair tools, RA Power Solutions delivers efficient and durable repairs without removing heavy castings.

For more on metal stitching and metal locking, metal stitching of engine block contact us today email us at rajshahani@rapowersolutions.com, info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs:

Metal stitching, also known as cold metal locking, is a mechanical repair process used to fix cracks in cast iron or cast steel components. It involves inserting stitching pins and locks to restore structural integrity—without welding or heat.

You should use thread repair inserts when original threads in an engine block, casing, or housing become stripped, worn out, or damaged. Helicoils restore the thread’s strength and allow secure fastening, even under high torque.

Yes. For cast iron and other brittle materials, metal stitching is safer and more reliable than welding. It avoids heat distortion, cracking, and structural weakening, which are common risks with welded repairs.

Absolutely. RA Power Solutions specializes in on-site metal stitching and thread repair, including work on marine vessels, power plants, offshore rigs, and remote industrial sites—without the need to remove the equipment.

These techniques can repair engine blocks, cylinder heads, gearboxes, cam case covers, pump casings, compressors, and more. These methods can typically restore any cracked or damaged cast iron or steel component.

One of our clients informed RA Power Solutions about damage to the cam case cover of a MAN diesel engine on board a vessel sailing near China. After reviewing the details and photographs, we observed that the cam case cover had broken into pieces. We also found that the threads on the engine body and … Continue reading “Metal Stitching and Thread Repair Inserts – RA Power Solutions”