RA Power Solutions has recently undertaken onsite repair of the crankshaft of Peroni pump manufactured and supplied by Peroni Pompe Italy. The crankshaft has three number of crankpin with a standard diameter of 215 mm, developed taper/ovality, and a rough surface. This problem caused frequent damage to the crankpin bearings, leading to major shutdown of the plant and heavy financial losses for the company.

The crankshaft of Peroni Pump manufactured by Peroni Pompe Italy, was inspected by RA Power Solutions technicians for the following parameters:

- Dimensional inspection of crankpin for taper & ovality. The ovality ranging from 0.06 mm to 0.18 mm was observed.

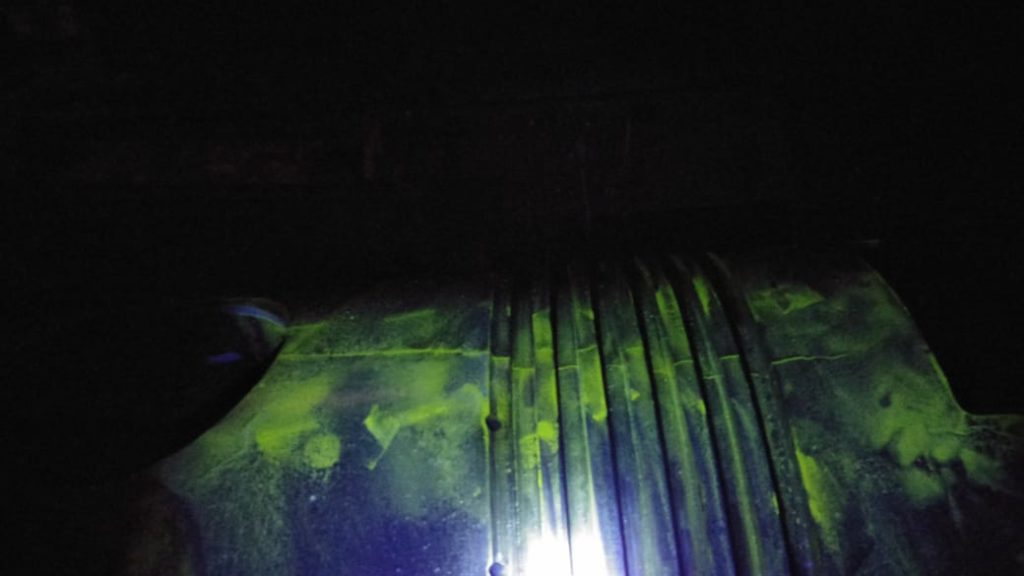

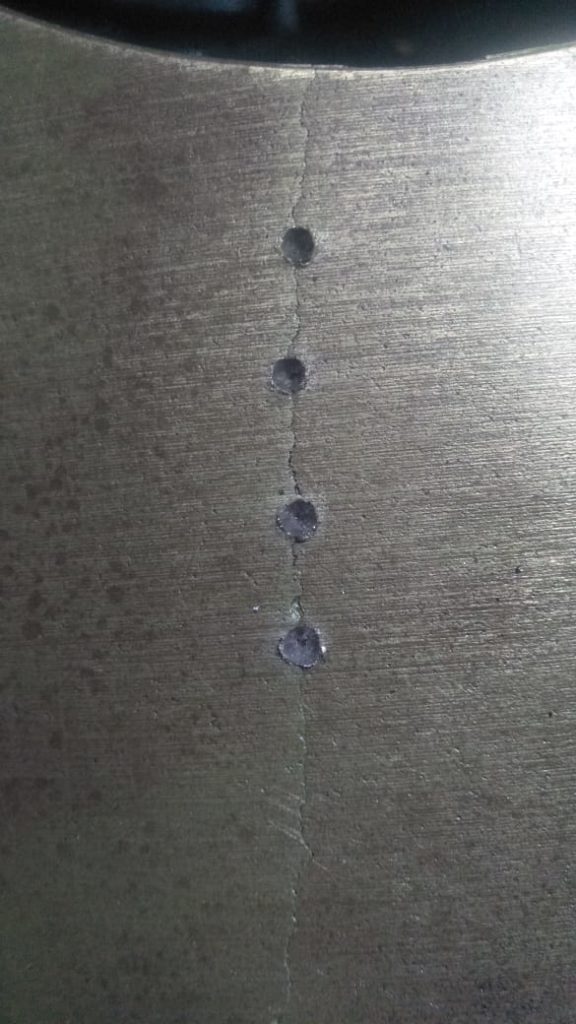

- The MPI test was conducted with a high-intensity Magnaflux torch and no abnormality was observed. Few superficial hairline cracks were observed, which may be due to rubbing of the crankshaft bearing steel lining with the crankpin diameter.

- The hardness of the crankpin was observed within limits.

- On visual inspection, bearing line marks and a rough surface was observed.

Action Taken by RA Power Solutions for Repair of Peroni Pompe Crankshaft:

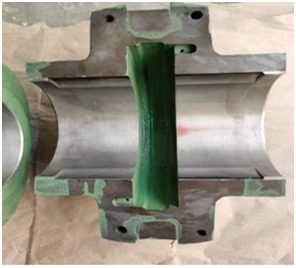

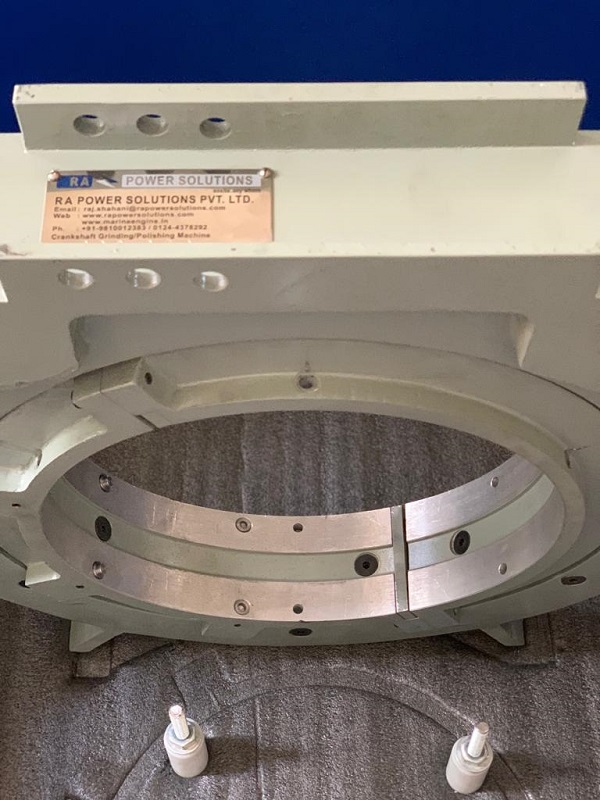

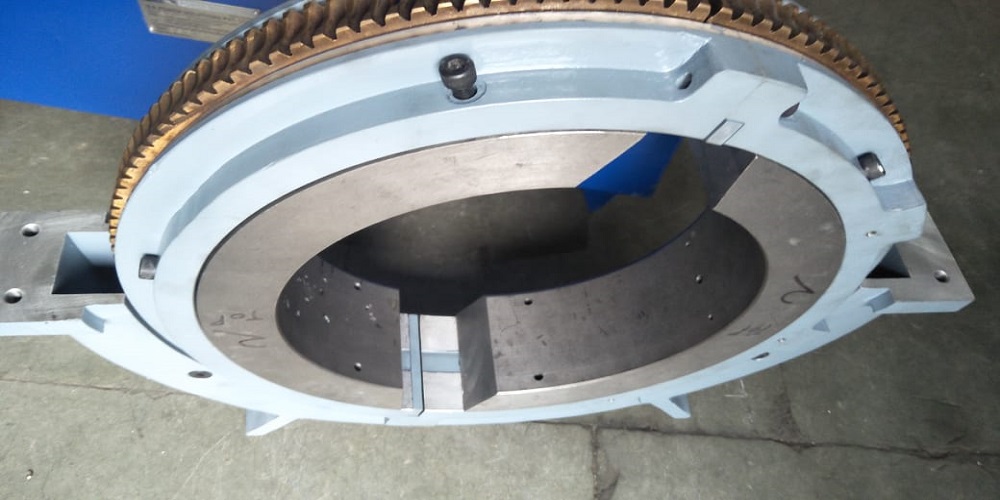

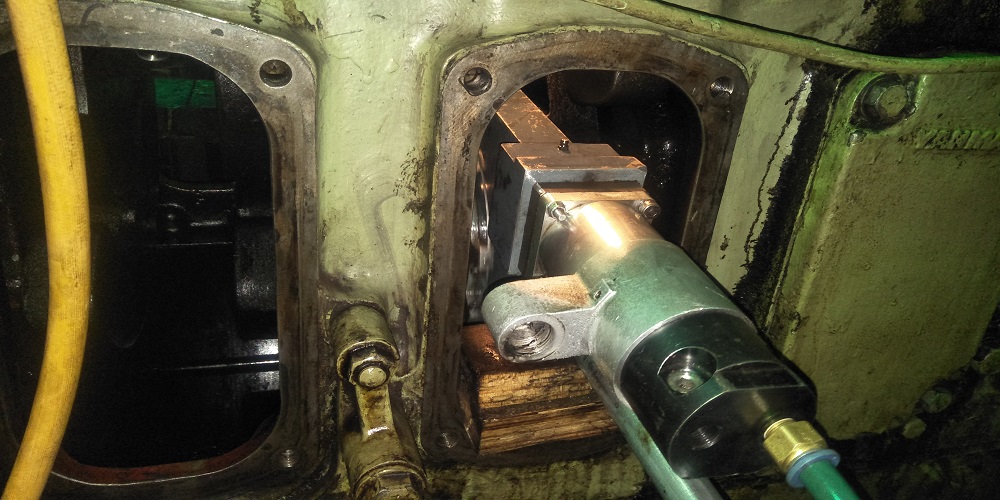

- It was jointly decided with the client to undertake grinding of all three crankpins to the first step size of 0.5mm.

- The grinding of crankpin was executed onsite, and the final diameter was maintained between 214.48 and 214.50 mm.

- We are giving below the dimensions of the crankpin before and after the grinding job was executed by RA Power Solutions.

Size of CR Journal

| A | Aa | C | Cc | B | Bb | Min | Max | Ovality | |

| CR-1 Before | 214.95 | 214.96 | 214.95 | 214.92 | 214.88 | 214.88 | 214.88 | 214.96 | 0.08mm |

| CR-1 After | 214.48 | 214.48 | 214.49 | 214.48 | 214.49 | 214.50 | 214.48 | 214.50 | 0.02mm |

| CR-2 Before | 214.88 | 214.89 | 214.92 | 214.94 | 214.88 | 214.93 | 214.88 | 214.94 | 0.06mm |

| CR-2 After | 214.48 | 214.50 | 214.49 | 214.48 | 214.50 | 214.49 | 214.48 | 214.50 | 0.02mm |

| CR-3 Before | 214.69 | 214.84 | 214.87 | 214.83 | 214.80 | 214.81 | 214.69 | 214.87 | 0.18mm |

| CR-3 After | 214.49 | 214.50 | 214.50 | 214.49 | 214.49 | 214.48 | 214.48 | 214.50 | 0.02mm |

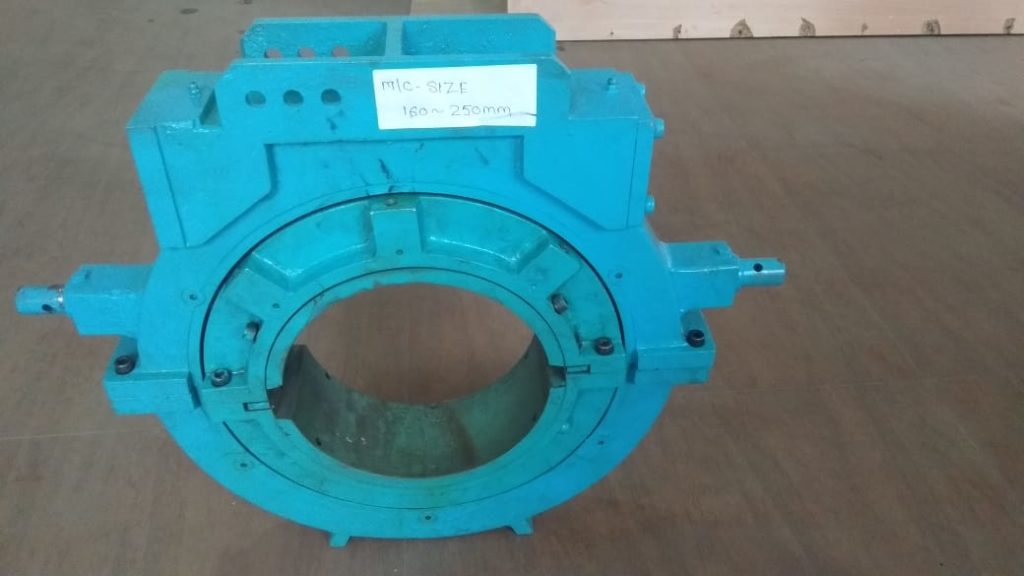

Undersize Crankpin Bearing for Peroni Pompe

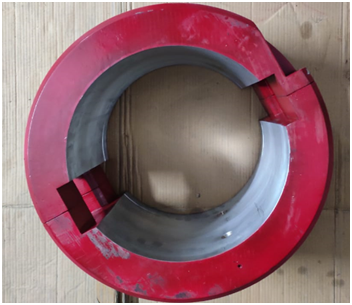

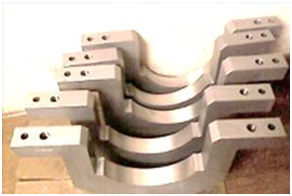

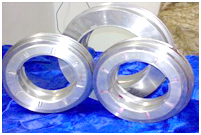

The crankpin bearings, undersized by 0.5 mm, were manufactured by RA Power Solutions and supplied to the client. The Peroni Pompe was commissioned, and the performance of the crankshaft and bearings was found satisfactory.

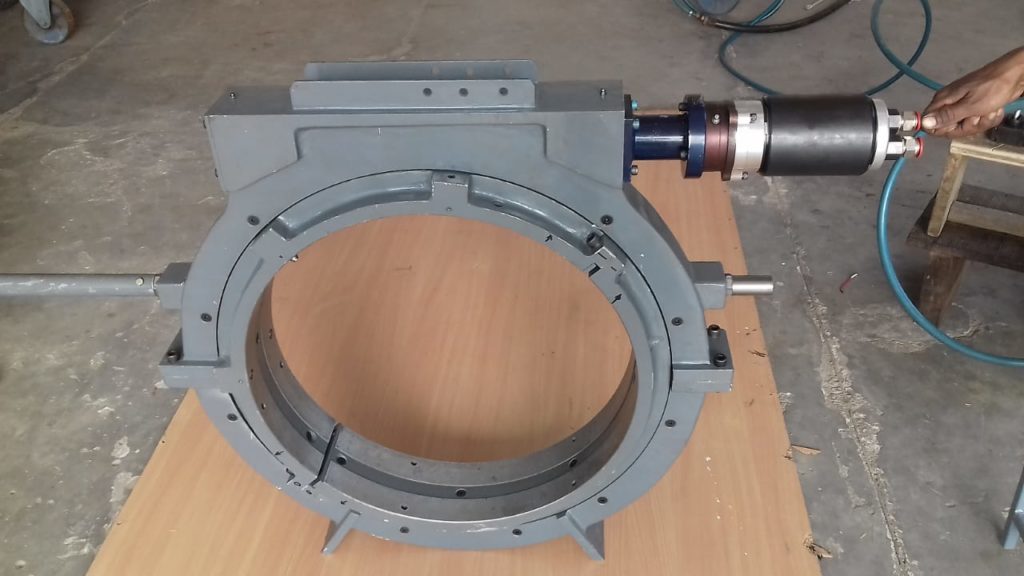

RA Power Solutions, with over 43 years of experience, specializes in onsite crankshaft repair for engines, compressors, pumps, forging hammers, and all rotating equipment. Our technicians have valid visas and can travel all over the world with the in-situ grinding machine to execute the repairs.

The author is Mr. Raj Shahani, Managing Director of the company. He has 43 years of experience in grinding crankshafts, polishing crankshafts, and all services related to engine and supporting equipment repair. He has designed and developed a portable crankshaft grinding machine to save time and money.

For more details, please email us at rajshahani@rapowersolutions.com, or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

RA Power Solutions has recently undertaken onsite repair of the crankshaft of Peroni pump manufactured and supplied by Peroni Pompe Italy. The crankshaft has three number of crankpin with a standard diameter of 215 mm, developed taper/ovality, and a rough surface. This problem caused frequent damage to the crankpin bearings, leading to major shutdown of the plant … Continue reading “Peroni Pompe Crankshaft Repair | Save Crankshaft From Rejection”