Connecting rods of high capacity, main and auxiliary engines are repaired by RA Power Solutions. Connecting rods during the operation of the engine are heavily stressed, transmitting power generated in the combustion chamber to the crankshaft. It is important that periodically or at the time of general overhauling, the condition of the connecting rod is checked, and either it is replaced or connecting rod is reconditioned.

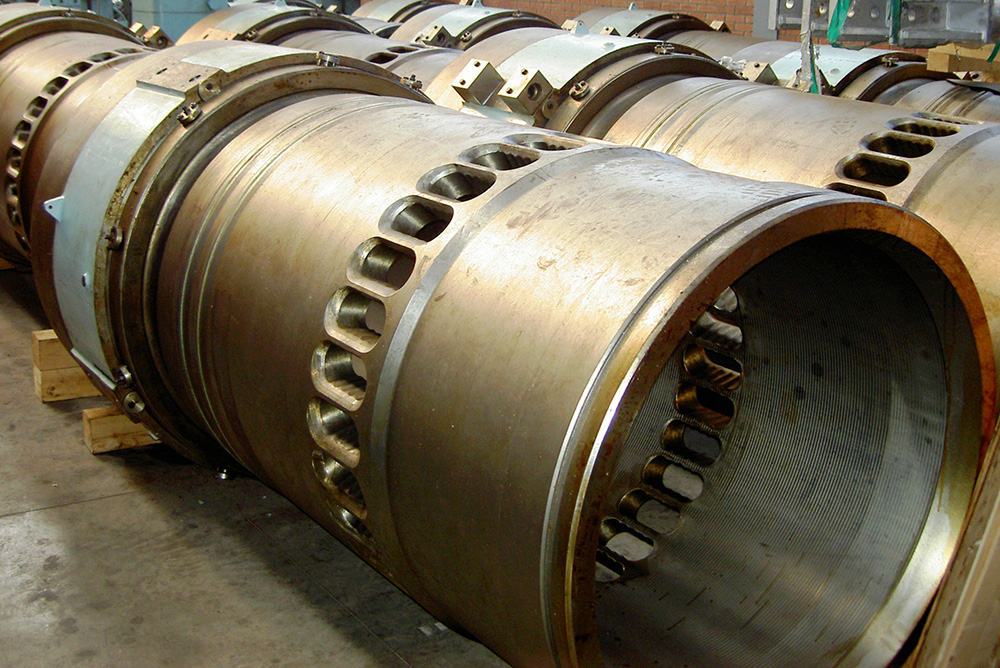

RA Power Solutions has four decades of experience in reconditioning of connecting rods up to the bore size of 500 mm.

Following process is adopted for successful reconditioning of connecting rods:

- Connecting rod is subject to chemical cleaning and shot blasting after dismantling.

- The big end and small end bore of connecting rod are checked and recorded

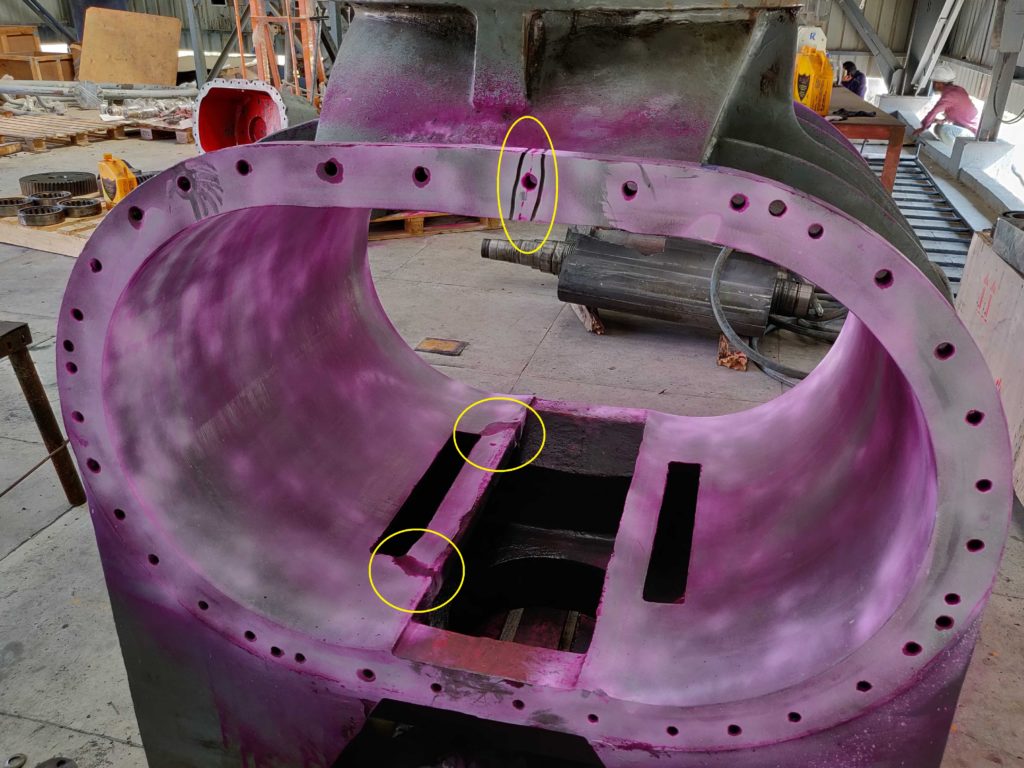

- Connecting rod is checked for cracks and overheating by MPI or Dye penetrant test.

- The serration of the joining face connecting rod bolts are also subject to crack detection.

- Center to center distance of big end bore and small end bore is also checked.

- Straightness of connecting rod is also checked.

The connecting rod’s big end and small end are re-machined/bored on the latest design of the boring machine equipped with DRDO. All the connecting rods repaired by us are guaranteed for satisfactory performance and are 100% check for quality.

We also maintain a large stock of repaired connecting rods which are reconditioned strictly as per the manufacturer’s specifications and tolerance. Generally, the cost of a reconditioned connecting rod is ¼ of the connecting rods sold by engine manufacturers.

We maintain the stock of connecting rod for the following engines:

Wartsila, Daihatsu, MWM, Caterpillar, Man, Mak, B&W, Sulzer, Bergen, Detroit Diesel, Stork Werkspoor, Pielstick, Deutz, Yanmar, MTU, Cummins, Nohab Polar, Caterpillar, Mitsubishi, Yanmar, Mak 551, Mak 552, Mak 453, Mak 451 AK , Mak 452 AK, Deutz 540 , Deutz 358 , Deutz 350, Pielstick PC 2.2 PC 2.5, Wartsila 524, Wartsila 824 TS, Sulzer 6 AL 25/30, Sulzer 5 AL 25/30 MWM TBD 484, MaN 40/54 , Man Sulzer 12 ASV 25/30, Sulzer 16 ZV 40/48, Deutz BV 16M 540, B&W 6L 45 GFCA, MAN B&W 55/GF, CAT D353, B&W 5T23LH, Daihatsu 6 PST 26D, Daihatsu 6 PSHTb 26M, Mak 6MU 451 AK, Deutz 6M 628, Caterpillar 3512, Deutz BV 12M 628, MWM TBD 234, WICHMANN 5AX, SKL 8NVD 48A-2U, Pielstick PC 2.2 LNR, Caterpillar 3508 and more.

The author of the blog is Mr. Raj Shahani, Managing Director of the company. He is having 40 years of experience in providing new and reconditioned marine engine spares like connecting rod, cylinder liners, cylinder head, crankshaft, heat exchangers, gaskets, camshaft, white metal bearings, and many more.

For more information regarding engine connecting rods, bearings for Daihatsu engine, bearings for Yanmar engine, and new and reconditioned engine spares with the guarantee, please email us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

Connecting rods of high capacity, main and auxiliary engines are repaired by RA Power Solutions. Connecting rods during the operation of the engine are heavily stressed, transmitting power generated in the combustion chamber to the crankshaft. It is important that periodically or at the time of general overhauling, the condition of the connecting rod is … Continue reading “Second-Hand Connecting Rods | Repair of Connecting Rods | Reconditioning of Connecting Rods – RA Power Solutions”