At RA Power Solutions Pvt. Ltd., we offer specialized cold metal locking and stitching services for repairing cracked or damaged engine blocks and cast components—without welding or heat damage.

Real-World Case Study: Wartsila 18V32 Engine Block Repair

- A power plant engine block of Wartsila 18V32 suffered catastrophic failure due to a connecting rod—and was estimated by OEM at 9 months delivery time and prohibitively high cost.

- RA Power Solutions completed the repair onsite, without dismantling the crankshaft or removing major parts, while it remained installed on its foundation. The damaged area exceeded 72″ × 42″.

- With over 45 years of experience and more than 1,300 major block repairs, we delivered a cost-effective, fast-response solution with a permanent outcome.

Why Choose Our Metal Locking & Stitching Service?

- Completely cold process — no heat input or welding means no thermal distortion or damage.

- Insitu crankshaft repairs—no transport or dismantling, meaning minimal downtime and operational disruption.

- Superior mechanical strength—the stitched repair often regains or exceeds original tensile capacity.

- Applications across materials—effective for cast iron, steel, and aluminum in engines, compressors, turbines, pump casings, and more.

- Dedicated, experienced technicians who can mobilize worldwide—Metal locking of Engine Block, including vessel boarding with Indian CDC clearance—for fast turnaround.

Our Repair Workflow:

| Step | Activity |

| Crack Detection | Magnetic particle inspection (MPI, Level 2 certified) identifies crack location, length, and severity. |

| Damage Preparation | Damaged sections are drilled and cleaned for accuracy. |

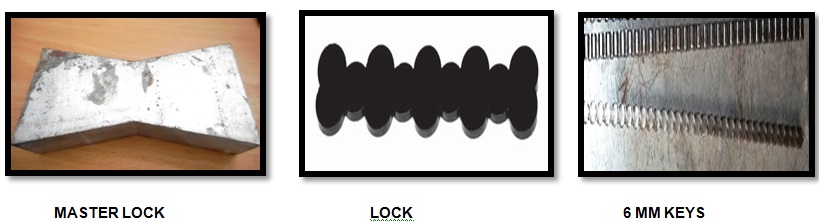

| Stitching Key Installation | Special pins and interlocking metal keys are inserted across the fracture. |

| Surface Finishing | Pins are ground flush; no further machining is required—original profiles are preserved. |

| Final Checks | Optional pressure testing ensures a gas- or water-tight seal when needed. |

For more details regarding metal stitching, metal locking services, repairing cast iron metal lock, cast iron repair, and Metal Locking of engine block at Low Price, email us your query at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs:

It’s a cold repair process to fix cracks in cast iron or steel engine blocks without welding.

Special pins and metal locks are inserted across the crack to restore strength without heat.

Yes, because it avoids heat distortion, maintains alignment, and prevents further cracking.

Cast iron, cast steel, aluminum, and other brittle metals.

Yes, RA Power Solutions offers in-situ repairs worldwide without dismantling the engine.

At RA Power Solutions Pvt. Ltd., we offer specialized cold metal locking and stitching services for repairing cracked or damaged engine blocks and cast components—without welding or heat damage. Real-World Case Study: Wartsila 18V32 Engine Block Repair A power plant engine block of Wartsila 18V32 suffered catastrophic failure due to a connecting rod—and was estimated by OEM … Continue reading “Metal locking of Engine Block by Experienced Technicians | Bangladesh”