In the world of marine, industrial, and power generation engines, crankshaft damage can bring operations to a standstill. Fortunately, onsite crankshaft repair and in situ crankshaft grinding services have revolutionized the way industries handle such emergencies, eliminating the need for disassembly or transportation.

What Is Onsite Crankshaft Repair?

Onsite crankshaft repair (also known as crankshaft repair onsite or on site crankshaft repair) refers to the process of repairing crankshaft damage directly at the site of operation. Whether on a vessel, power plant, or offshore platform, this service ensures minimal downtime and cost-effective solutions. The combination of onsite crankshaft grinding and repairing results in extended crankshaft life and improved engine performance.

In Situ Crankshaft Grinding: The Modern Solution

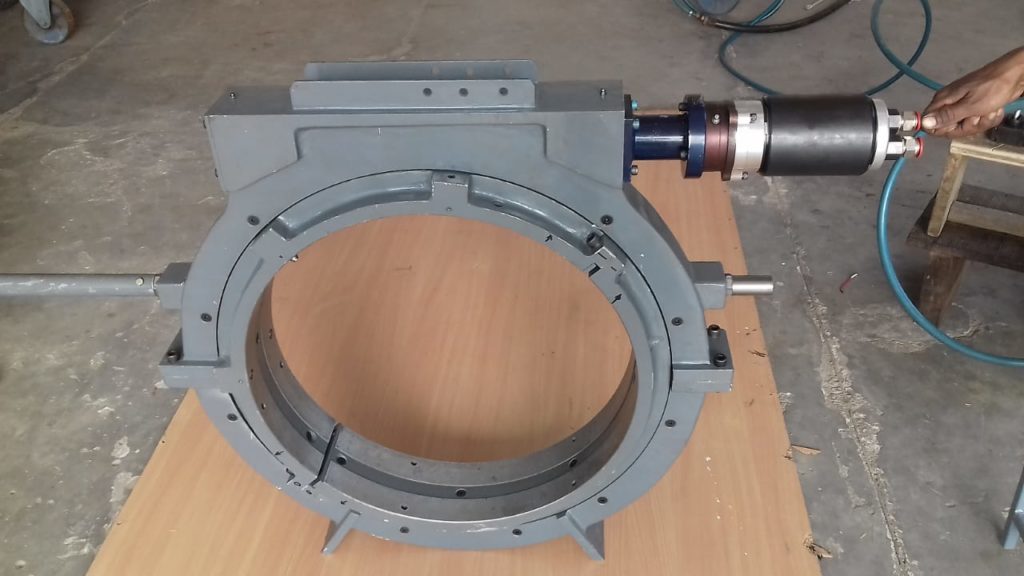

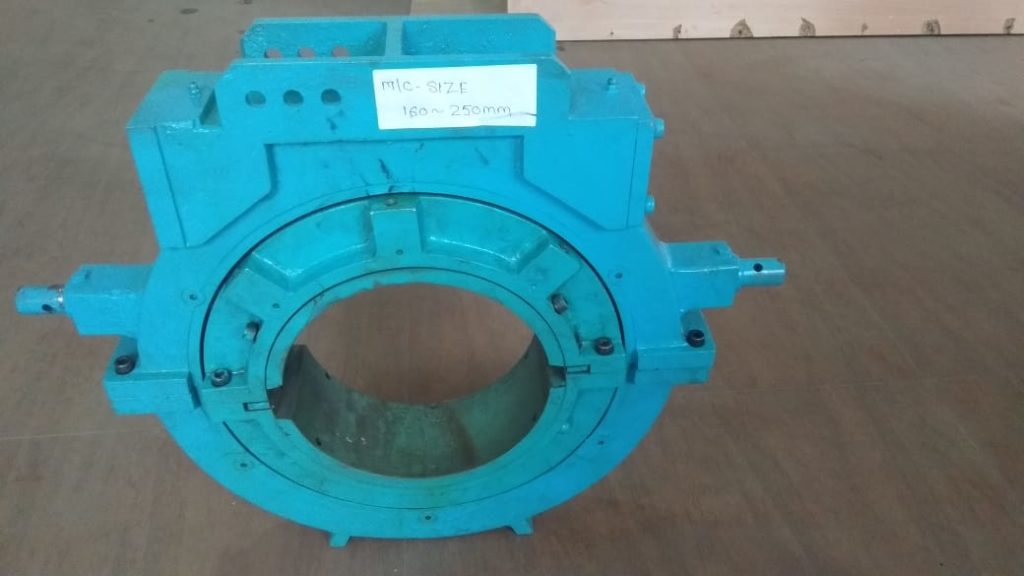

In situ crankshaft grinding, also known as insitu crankshaft grinding, is a specialized process where the crankshaft is ground in its original position using a customized onsite crankshaft grinding machine. This technique ensures perfect alignment and eliminates the need for dismantling. Our team provides advanced onsite crankshaft grinding services, ensuring the crankpins and main journals are restored to the original manufacturer’s specifications.

Why Choose In Situ Crankshaft Repair Services?

- Fast turnaround

- Eliminates transportation costs

- Precision results with portable machines

- Minimal downtime and disruption

- Environmentally friendly approach

Complete Onsite Crankshaft Grinding and Polishing

After grinding, the next critical step is crankshaft polishing. Our crankshaft polishing services use high-grade abrasives to enhance surface finish and increase longevity. The combination of onsite crankshaft grinding and polishing results in extended crankshaft life and improved engine performance.

Crankpin Repair and Insitu Machining Expertise

We specialize in onsite crankpin repair, which involves insitu machining of the crankpin to restore it to its standard size and finish. Our technicians use precision-engineered tools for insitu grinding of crankpins, ensuring accurate geometry and surface integrity.

With years of experience in insitu crankshaft machining, we have developed efficient solutions for all types of crankshaft issues, including scoring, taper wear, and journal ovality.

High-Precision In Situ Crankshaft Machining Services

In situ crankshaft machining or on site crankshaft machining is the ideal solution when engine components are too large or critical to be moved. We deploy skilled engineers with portable tools to provide in situ crankshaft machining with micron-level accuracy.

Our in situ crankshaft repair services are trusted worldwide for large engine applications including marine engines, diesel generators, and industrial compressors.

Why Our Services Stand Out

We utilize a state-of-the-art in situ crankshaft grinding machine that can handle crankshafts up to 700mm in diameter. Our mobile teams are available globally to deliver emergency onsite crankshaft grinding repair and insitu crankshaft grinding repair anytime, anywhere.

With our holistic approach, we cover every aspect:

- Onsite crankshaft grinding and repair

- Insitu crankshaft machining

- Insitu machining & polishing of crankshaft

- In situ machining and repair of crankshaft

When engine downtime is not an option, trust our expert in situ crankshaft repair services. With advanced tools, skilled technicians, and decades of experience, we offer the most reliable onsite crankshaft grinding, crankshaft repair on site, and crankpin repair solutions globally. For efficient, cost-effective, and precision onsite crankshaft grinding services, contact our team today and keep your engines running smoothly.

FAQ

Onsite crankshaft repair is a broader term that includes all types of crankshaft repair work done at the client’s location. In situ crankshaft grinding is a specific process within that service, involving precision grinding of the crankshaft journals or crankpins in their original position using portable machines.

Yes, our in situ crankshaft grinding and repair services allow us to perform repairs without dismantling the crankshaft from the engine, saving time and reducing costs.

The duration depends on the extent of damage and the number of crankpins or journals to be repaired. Typically, a single crankpin can be ground within 24–30 hours, including inspection, setup, and final polishing.

We service marine engines, diesel power plant generators, offshore equipment, and large industrial compressors. Our technicians are experienced in handling all major engine makes and models.

Our portable in situ crankshaft grinding machine can handle crankshafts up to 700 mm in diameter.

In the world of marine, industrial, and power generation engines, crankshaft damage can bring operations to a standstill. Fortunately, onsite crankshaft repair and in situ crankshaft grinding services have revolutionized the way industries handle such emergencies, eliminating the need for disassembly or transportation. What Is Onsite Crankshaft Repair? Onsite crankshaft repair (also known as crankshaft … Continue reading “Onsite Crankshaft Repair And In Situ Crankshaft Grinding Services – Comprehensive Guide”