Experts highly recommend metal stitching and metal locking for repairing cracks in cast iron. Industries around the world use this cold repair technique because it delivers reliable and effective results when restoring cast iron components.

Broken cast iron pieces can also be replaced by a new piece of casting undertaking metal locking. This technology is as old as the introduction of cast iron casting in industry.

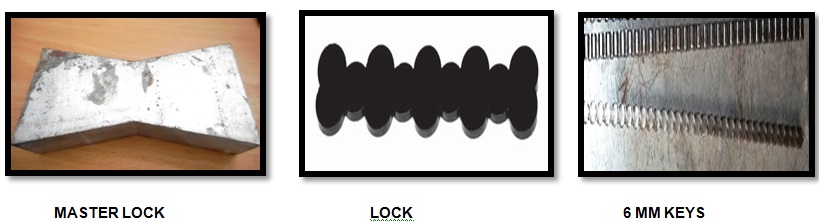

Metal keys and metal locks are used to undertake crack repair in cast iron casting.

RA Power Solutions Pvt. Ltd. has a team of trained technicians who carry out metal stitching of broken or cracked castings directly onsite. They bring all necessary tools, consumables, and, if needed, a replacement casting to the site. The team repairs the crack onsite and avoids any need to disassemble or transport the equipment.

Tests and experience show that metal stitching repairs can strengthen cracked castings. The repaired section often becomes even more durable after the process. We execute crack repairs on board the vessel, in power plants all over the world.

Why Choose Cold Repair Over Welding?

Traditional welding uses heat to damage alignment, change grain structure, and weaken cast iron components. Cold repair procedures such as metal stitching and locking maintain the original material integrity. This results in stress-free, distortion-free, and high-strength solutions.

What Is Metal Stitching & Metal Locking?

Metal stitching is a cold bolt-locking process that includes drilling precise holes along a crack and inserting metal “keys” and studs into a dovetailed pattern. These studs bite into one another, tightening the crack and restoring structural rigidity.

Metal locking supports stitched joints with custom-shaped metal inserts, inhibiting additional proliferation and boosting long-term endurance.

We extend metal stitching services all over the world, including countries like Madagascar, Oman, Qatar, Philippines, Bahrain, Srilanka, Bangladesh, Myanmar, Turkey, Nigeria, Greece, Saudi Arabia, UK, Dubai, Singapore, Malta, and Cyprus, etc.

For more information on crack repair by metal stitching, Cast Iron Crack Repair, cast iron stitching, repair cast iron, cast iron metal stitching services, crack repair in cast iron, and repairing cast iron metal lock, contact us at rajshahani@rapowersolutions.com or info@rapowersolutions.com or call us at +91 9582647131, or +91 9810012383.

FAQs:

Metal stitching is a cold repair process used to restore cracked or damaged cast iron components. It involves inserting special metal keys and locking pins across the crack to mechanically join and seal it—without using heat or welding.

While both methods are used together, metal locking adds reinforcement by embedding strong metal locks or inserts that cross the crack. These locks increase structural integrity and prevent further crack propagation.

Welding applies heat that can distort the casting and cause new cracks due to thermal stress. In contrast, metal stitching is a cold process, meaning there’s no heat, no distortion, and the original metallurgical properties remain intact.

Experts highly recommend metal stitching and metal locking for repairing cracks in cast iron. Industries around the world use this cold repair technique because it delivers reliable and effective results when restoring cast iron components. Broken cast iron pieces can also be replaced by a new piece of casting undertaking metal locking. This technology is … Continue reading “Cast Iron Crack Repair with Metal Stitching & Metal Locking”