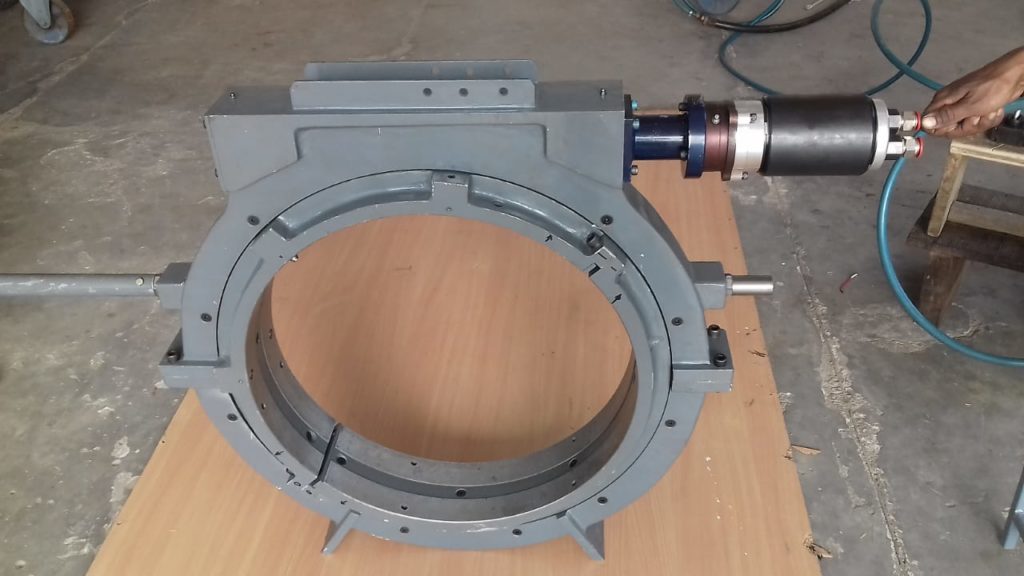

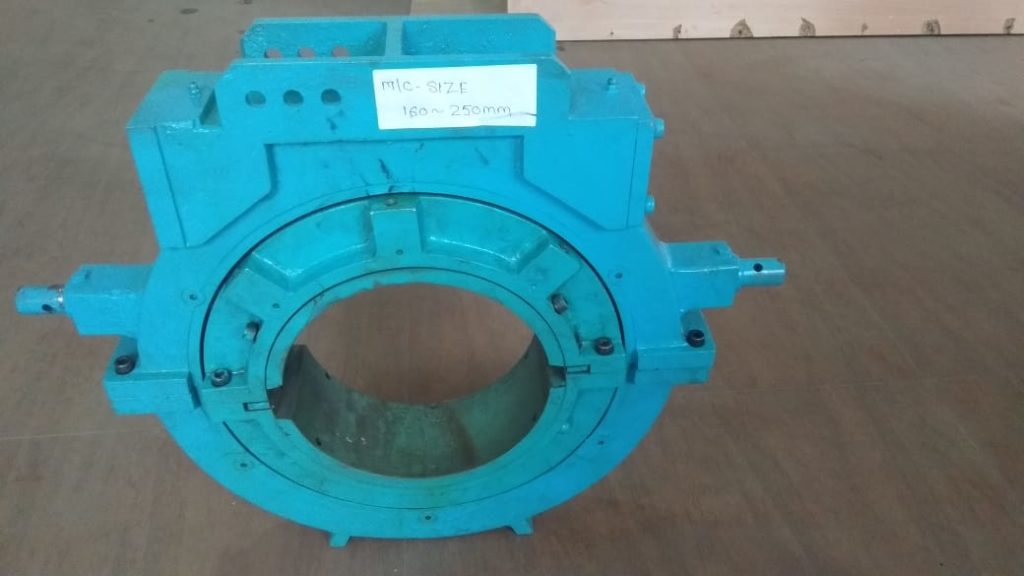

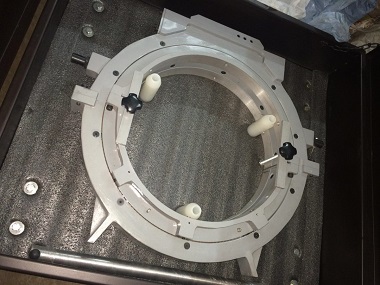

Onsite crankshaft grinding machine is a specialised machine that is used to manufacture, repair, and recondition crankshafts on site. The engine’s backbone is the crankshaft, which converts piston motion into rotation. Consequently, its precision is essential. Crankshafts can develop surface imperfections, erosion, or scoring over time. Through the restoration of engines to their exact proportions with a faultless finish, our machine guarantees their dependability and efficiency.

RA Power Solutions is emerging as a worldwide supplier of such machines, enabling engine and repair shops, power plants, and marine operators to carry out crankshaft repairs without removing them from the engine block.

Important Features:

- A finish that meets international standards is achieved through high-precision grinding, which maintains strict tolerances of less than 10 microns.

- It is portable and lightweight, allowing for immediate on site crankshaft maintenance at the designated location.

User-Friendly:

- This device is suitable for both novice and seasoned technicians, as it is designed to be low-maintenance and trouble-free.

- A Wide Range of Applications: It is suitable for marine engines, power plants, and heavy industrial apparatus, as it does not necessitate disassembly.

Applications:

- Marine Industry: Large ship engines can be repaired on site without the need for removal.

- The crankshafts of diesel generators function effectively in power facilities.

- Heavy engineering is suitable for the construction of buildings, mining, and industrial machinery.

Benefits:

- Restoring crankshafts rather than replacing them with costly alternatives results in cost savings.

- Increased Engine Life: Prevents deterioration and extends the lifespan of the engine.

- The advantage of onsite repair is that it eliminates the necessity of transporting large engines to workshops.

- Enhanced Performance: Ensures a smoother operation, reduced fuel consumption, and reduced friction.

- Time-saving: Restoration can be completed more rapidly than the process of obtaining new materials.

Global Presence:

Over 200 Onsite Crankshaft Grinding Machines and crankshaft grinding and polishing equipment have been supplied globally by RA Power Solutions. Our apparatus is utilised in the following regions:

- Asia: India, Saudi Arabia, the United Arab Emirates, Indonesia, Sri Lanka, and Bangladesh

- Africa: Burkina Faso, Tanzania, Ghana, Kenya, Egypt, South Africa, and Nigeria

- Greece, Turkey, Italy, Germany, the United Kingdom, and the Netherlands comprise Europe.

- Americas: the United States, Canada, Mexico, and Brazil

- Oceania comprises Australia and New Zealand.

We are committed to enhancing the profitability of transportation companies, repair shops, power plants, and heavy industries by reducing costs, minimizing downtime, and expanding our global presence.

For additional information about the Onsite Crankshaft Grinding Machines, Onsite Crankshaft Grinding Equipment. Please contact us at rajshahani@rapowersolutions.com, info@rapowersolutions.com, or +91 9582647131 or +91 9810012383.

FAQs:

Onsite crankshaft grinding (in situ grinding) is a process where damaged crankpins or main journals are repaired using portable grinding machines directly at the site, without dismantling the engine.

The key benefits include reduced downtime, lower repair costs, elimination of transportation hassles, precision repairs meeting OEM standards, and extended crankshaft life.

These machines are widely used in marine, power plants, diesel generator sets, offshore platforms, heavy engineering, and industrial plants where large engines are in operation.

RA Power Solutions machines can handle a wide range of crankshaft diameters, from small engines to large marine and industrial engines, with high accuracy.

Yes, RA Power Solutions supplies crankshaft grinding machines globally and provides operator training to ensure easy and efficient use at any site.

Onsite crankshaft grinding machine is a specialised machine that is used to manufacture, repair, and recondition crankshafts on site. The engine’s backbone is the crankshaft, which converts piston motion into rotation. Consequently, its precision is essential. Crankshafts can develop surface imperfections, erosion, or scoring over time. Through the restoration of engines to their exact proportions … Continue reading “Onsite Crankshaft Grinding Machines – Worldwide Supplier”