With over 45 years of global experience, R A Power Solutions specialises in the onsite repair of cracked and damaged components using advanced metal stitching and Metalock techniques. We regularly undertake metal stitching and metalocking for heavy industrial parts made from cast iron, cast steel, aluminium, bronze, and other critical engineering materials.

Components We Repair Using Metal Stitching & Metalock

We carry out onsite crack repair for a wide range of industrial components, including:

- Bedplates

- Forging hammers

- Compressor bodies

- Engine blocks and major engine components, such as cylinder liners and cylinder heads

- Gearbox housings and similar heavy-duty castings

High-Quality Tools & Consumables for Reliable Repairs

Successful metal stitching requires precision, skill, and the right equipment. To ensure long-lasting repairs, we use:

- Premium Pneumatic Tools

- Imported pneumatic tools from leading U.S. manufacturers

- Essential for preparing accurate profiles before stitching

- Ideal for remote sites due to easy availability of compressed air

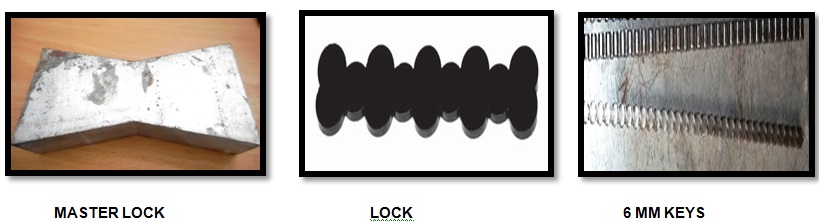

Specialized Metal Locks & Keys

Our repairs use high-grade metal locks, keys, and master locks. Selection is based on a metallurgical analysis of the damaged casting.

We always select consumables with superior properties compared to the parent material, ensuring a durable and high-strength repair.

Key Features of the Metalock Process

- Cold process — no heat, no distortion, no stress on castings

- Precisely placed locks mechanically reinforce cracked sections

- Restores structural integrity without welding

- Ideal for engines and heavy machinery where alignment is critical

Advantages of Metal Stitching with Metal Keys

- Keys are inserted across the crack to seal and tighten the casting

- Overlapping patterns distribute load evenly

- Repaired areas often become stronger than the original casting

- Suitable for cast iron, aluminium, bronze, and cast steel

- Cost-Effective Repair Solution

Metal stitching and metal locking provide a highly cost-efficient alternative to component replacement. Many industrial parts are:

- Expensive to replace

- Long lead-time items

- No longer manufactured

- Repairing them onsite saves money, reduces logistics, and keeps operations running smoothly.

- Fast, Onsite, and Minimum Downtime

Metal stitching, a fast repair method, often enables completion within hours, directly at the site, without the need to dismantle the equipment. Metal stitching is a fast repair method that can typically be completed within hours, directly at the site, without dismantling the equipment. This drastically reduces downtime and allows machinery to return to service quickly.

Global Onsite Crack Repair Services

R A Power Solutions delivers onsite metal stitching, metalocking, engine block repair, and cast iron crack repair services in major industrial regions worldwide. Our teams are actively working on several international projects, providing reliable, high-precision solutions for critical equipment.

Contact Us

For inquiries or technical assistance:

📧 rajshahani@rapowersolutions.com

📧 info@rapowersolutions.com

📞 +91 9582647131, +91 9810012383.

With over 45 years of global experience, R A Power Solutions specialises in the onsite repair of cracked and damaged components using advanced metal stitching and Metalock techniques. We regularly undertake metal stitching and metalocking for heavy industrial parts made from cast iron, cast steel, aluminium, bronze, and other critical engineering materials. Components We Repair … Continue reading “Metalock | Metal Stitching | Repair of Cracked Components”