Metal Stitching And Metal Locking Services

Metal Stitching, also known as Cold Metal Repair or Metal Locking, is a means to restore broken cast iron, cast steel, or aluminum without welding or heat.

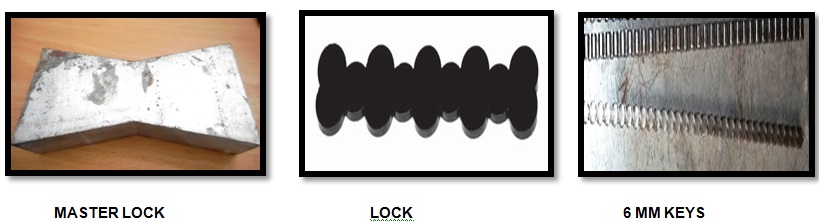

Instead of melting the metal like welding does, this method uses specially designed metal keys and stitching pins (locks) to pull the cracked edges together and seal the fracture permanently.

It’s a common fix in heavy industries like,

- Marine engine blocks and crankcases

- Turbine casings and power plants

- Covers for pumps, compressors, and generators

- Big machines are used in industry

Why Not Just Weld It?

It sounds straightforward to weld on cast parts, but in reality, it’s not:

- Heat makes things bend.

- The metal gets weaker because the way its parts work changes.

- There may be new cracks around the welded area.

- Metal stitching doesn’t have any of that because there is no heat.

- The casting’s original strength stays the same.

How the locks and keys really work

The magic of metal stitching lies in installing metal keys and stitching pins directly into the crack.

How to do metal stitching step by step

Step 1: Stop the Crack from Spreading

- Small holes are drilled at each end of the crack.

- This freezes the crack in place.

Step 2: Install Metal Keys (Locks)

- Slots are carefully machined along the crack.

- Precision metal keys are inserted into the slots.

What the keys do:

- Pull both sides of the crack tightly together

- Distribute stress across the repaired area

- Restore strength equal to — or even stronger than — the original casting

Step 3: Install Stitching Pins

- Small holes are drilled which are perpendicular to the crack.

- To seal the crack, metal stitching pins were screwed.

What the pins do:

- Hold the area in compression

- Make the repair pressure-tight (no leaks — oil, gas, or coolant)

Step 4: Finishing

- The repaired surface is machine-smooth and flush.

- After finishing, you can barely tell the crack existed.

Why Metal Stitching is a Game Changer

Benefit: What it means

- No heat involved, no distortion, no internal metal damage

- Strong reinforcement: Strength equal to or greater than the original casting

- Leak-proof, Perfect for high-pressure applications

- Work done on-site. No dismantling, minimal downtime

- Saves money: 60–80% cheaper than replacing the component

Where We Typically Use It

- Cracked diesel engine blocks

- Turbine or pump casings

- Compressor housings

- Marine engine frames and bedplates

- Generator casings

Metal Stitching And Metal Locking Services uses precision tools, keys, and locks to repair cracks in damaged engine blocks without heat, without distortion, and without messing with the metal’s original strength.

Why R A Power Solutions?

We’re not new to this — we’re experts at this.

With 45+ years of experience and thousands of successful repairs globally, R A Power Solutions repairs:

- Engine blocks

- Turbine and pump casings

- Cylinder liners

- Compressor housings

For more information , see the metal stitching and metal surgery process, Metal Stitching And Metal Locking Services, crack casting repair, turbine casing crack repair on site, and crack repair and damaged casting rectification. We also provide crankshaft grinding repair services, crankshaft grinding machines, rebabbitting bearings, etc. Contact us at rajshahani@rapowersolutions.com, info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

Metal Stitching And Metal Locking Services Metal Stitching, also known as Cold Metal Repair or Metal Locking, is a means to restore broken cast iron, cast steel, or aluminum without welding or heat.Instead of melting the metal like welding does, this method uses specially designed metal keys and stitching pins (locks) to pull the cracked … Continue reading “Metal Stitching & Metal Locking Services for Marine and Power Plants “