When cast-iron or aluminum engine blocks crack, the traditional fix—welding—is often expensive, risky, and destructive. At RA Power Solutions, we specialize in advanced cold repair techniques—metal stitching and metal locking—that restore structural strength without applying heat, requiring machining, or dismantling equipment.

With the improvement in repair technology now, it is possible to repair the crack in cast iron, steel, or aluminium component by metal stitching and metal locking process. The main feature of repair of crack or damaged casting by metal stitching, metal locking, and metal surgery is that process does not require disassembly of the equipment and taking the crack or damaged part to the workshop.

What Are Metal Stitching & Locking?

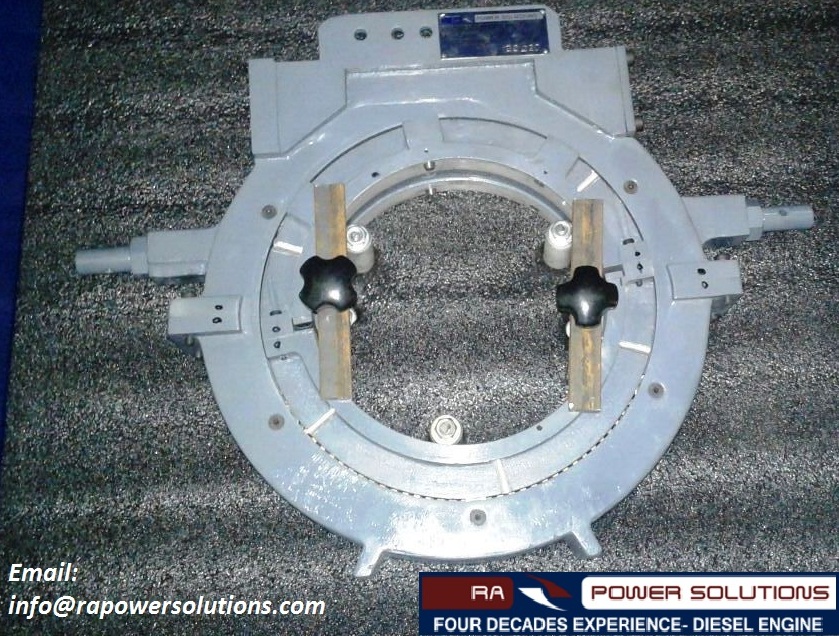

- Metal Stitching is a precise, cold repair method. Technicians drill a series of aligned holes across the crack, insert metal “keys” or studs into a dovetailed pattern, and tighten them so they interlock—effectively sealing the fracture and restoring rigidity.

- Metal Locking reinforces the stitching with custom-shaped metal inserts that prevent the crack from spreading further and enhance the repair’s long-term durability

RA Power Solutions has the team of experience technicians. They can travel to the site with tools and consumables required for metal stitching and metal locking undertake the repair.We repair cracks by metal locking and metal stitching while maintaining the original profile. In most cases, the process does not require any machining. Scientific tests prove that the repaired crack portion has greater tensile strength than before.

RA Power Solutions with the experience of forty five years in this field extends metal locking and metal stitching services for repair of damaged casting. We can also execute the repair while the vessel is sailing. We offer the lowest cost compared to our competitors.

Metal Stitching | Repair Cast Iron | Cast Iron Repair

Get your crack or broken components manufactured out of cast iron, cast steel or aluminium repair by metal stitching and metal locking process. RA Power Solutions with experience of more than four decades have successfully repaired thousands of major engine components and components installed in heavy industries all over the world.

The damage to the component may be serious, or the cracks are multiple. RA Power Solutions engineers have the experience, know how and necessary tooling to execute the most complicated and serious damage which takes place due to accidents in cast iron, cast steel and aluminium casting.

For more information on cold metal stitching engine block, cast iron engine block repair, metal stitching surgery, metal stitching engine block, repair cast iron, and metal stitching of engine block please email us at rajshahani@rapowersolutions.com or info@rapowersolutions.com, or call us at +91 9582647131 or +91 9810012383.

FAQs:

Metal stitching involves drilling a series of aligned holes across a crack, inserting interlocking metal keys or studs, and tightening them to seal the fracture. Metal locking uses custom-shaped inserts that reinforce and prevent crack propagation.

No. We perform the repairs in situ, without disassembling the machinery or removing the damaged part from its position

We maintain the original profile after metal stitching and locking, and in most cases, no machining is needed afterward

Yes. Scientific studies show that crack areas repaired by metal stitching and locking often have greater tensile strength than before

Absolutely. We can execute repairs while the vessel is sailing, minimizing downtime and logistical challenges

When cast-iron or aluminum engine blocks crack, the traditional fix—welding—is often expensive, risky, and destructive. At RA Power Solutions, we specialize in advanced cold repair techniques—metal stitching and metal locking—that restore structural strength without applying heat, requiring machining, or dismantling equipment. With the improvement in repair technology now, it is possible to repair the crack … Continue reading “Metal Stitching | Metal Locking | Repair of Cast Iron by Metal Stitching – RA Power Solutions”